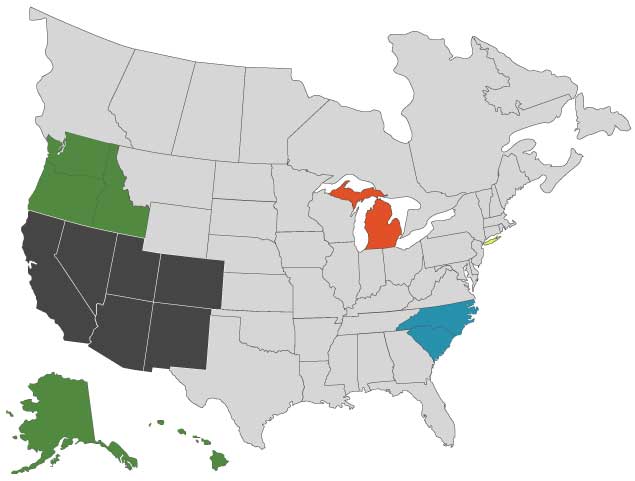

Perforated Metal

Perforated metal is a simple process of using a press to punch holes out of a piece of metal. Here are 3 different variations to that manufacturing process that can influence your design.

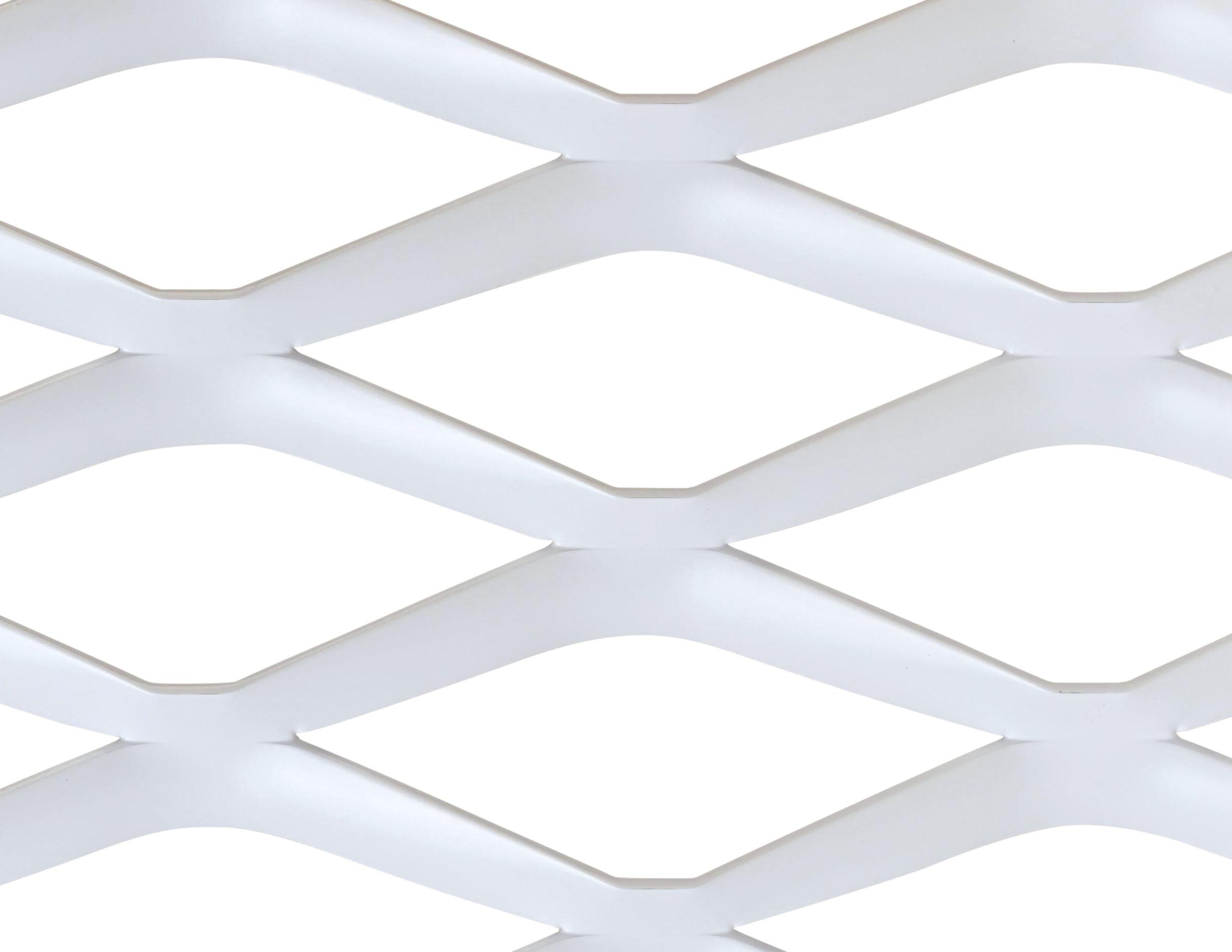

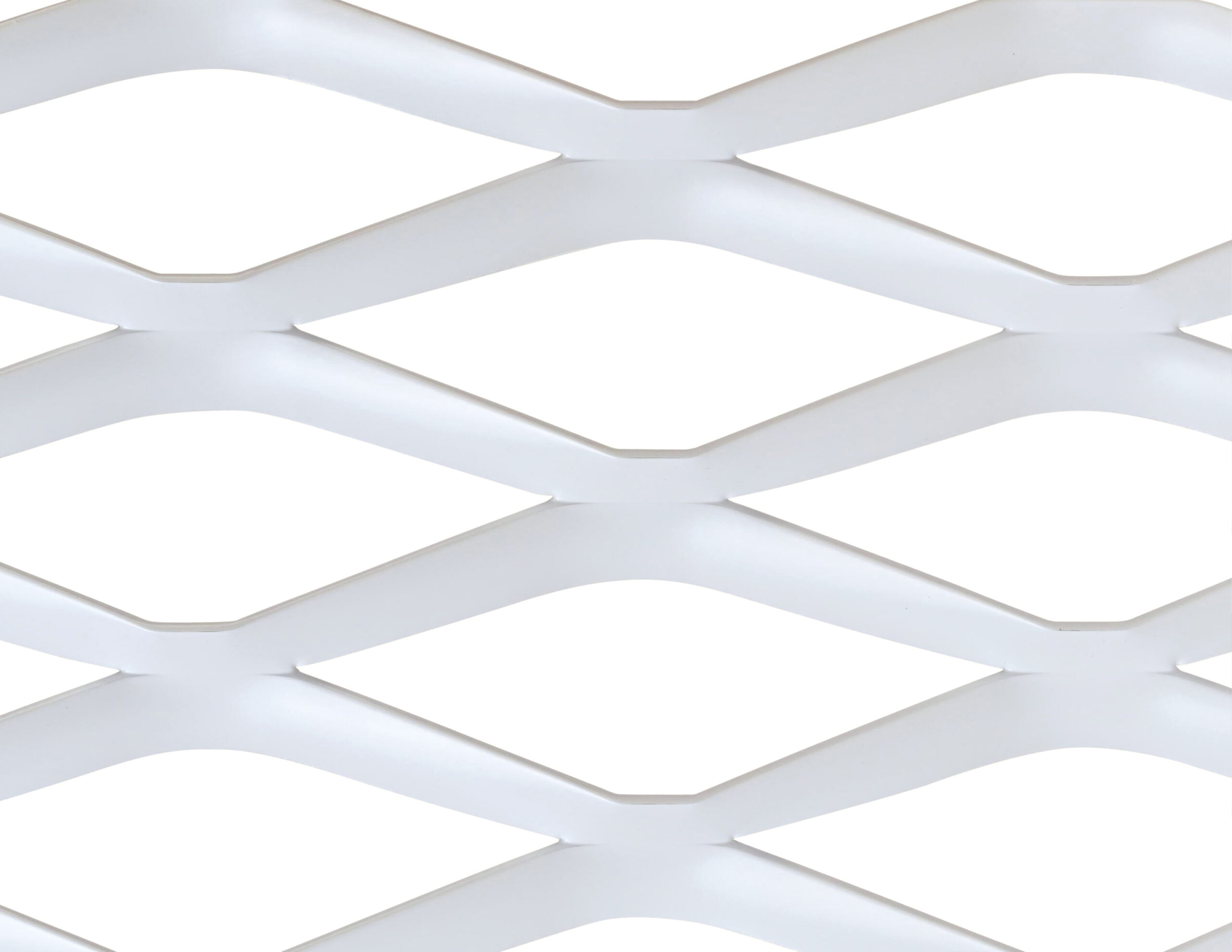

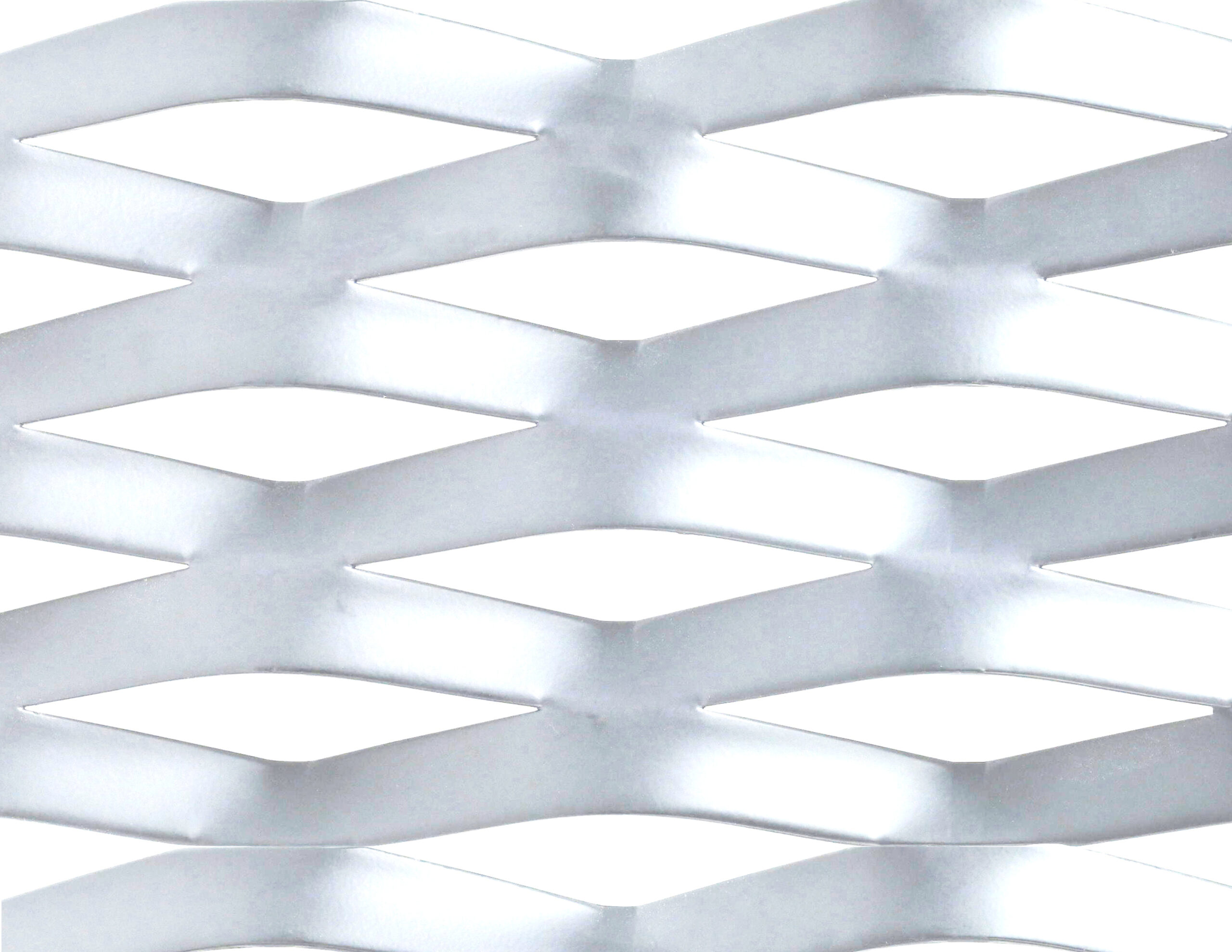

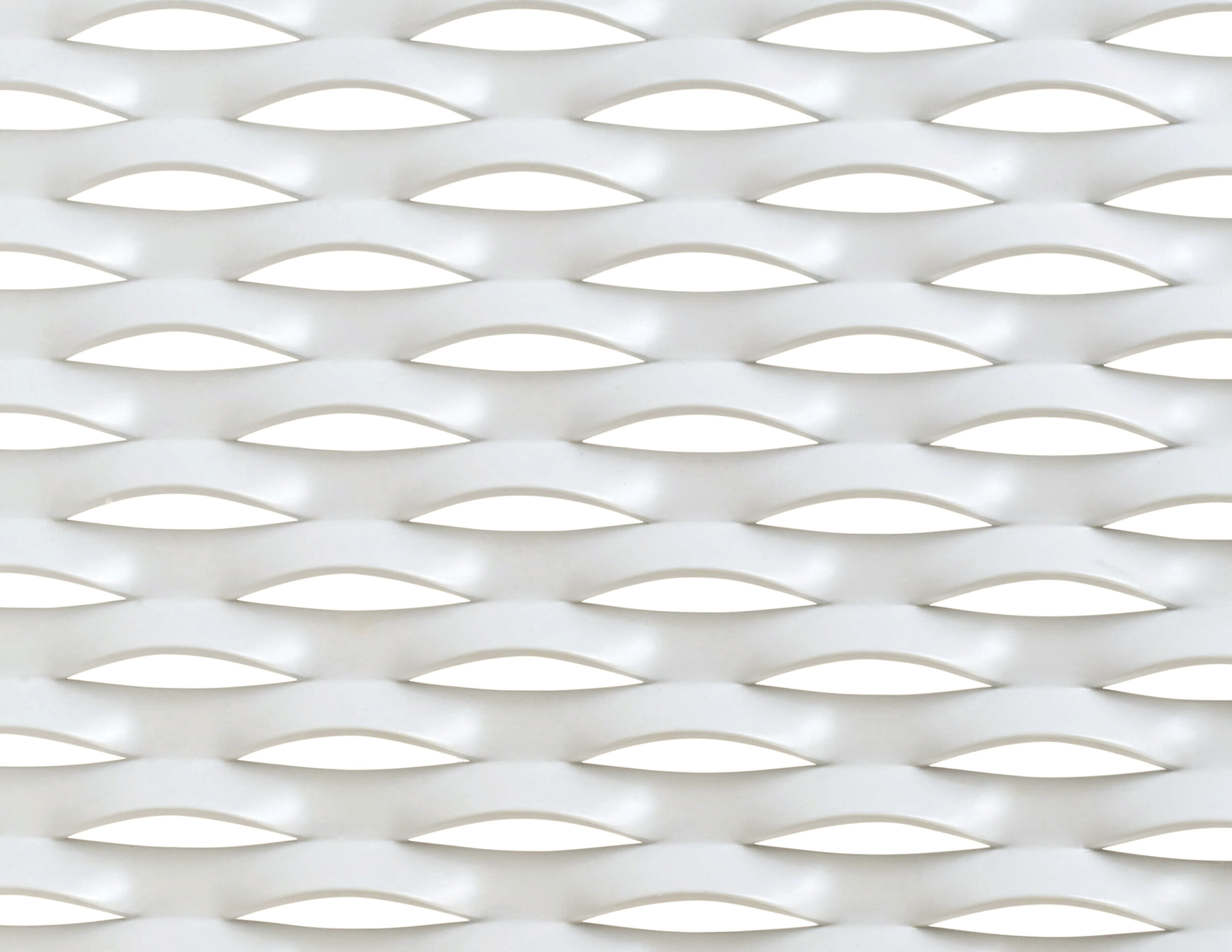

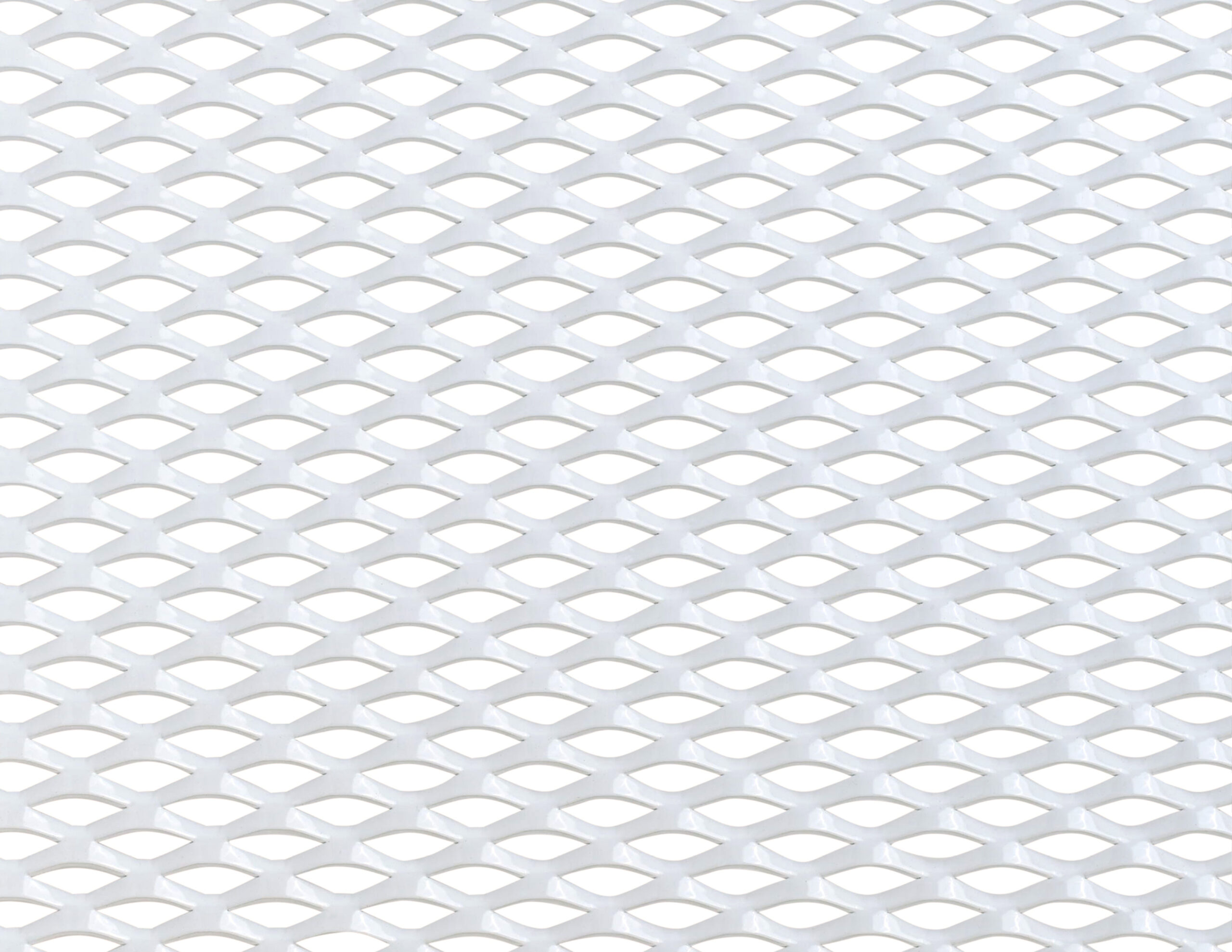

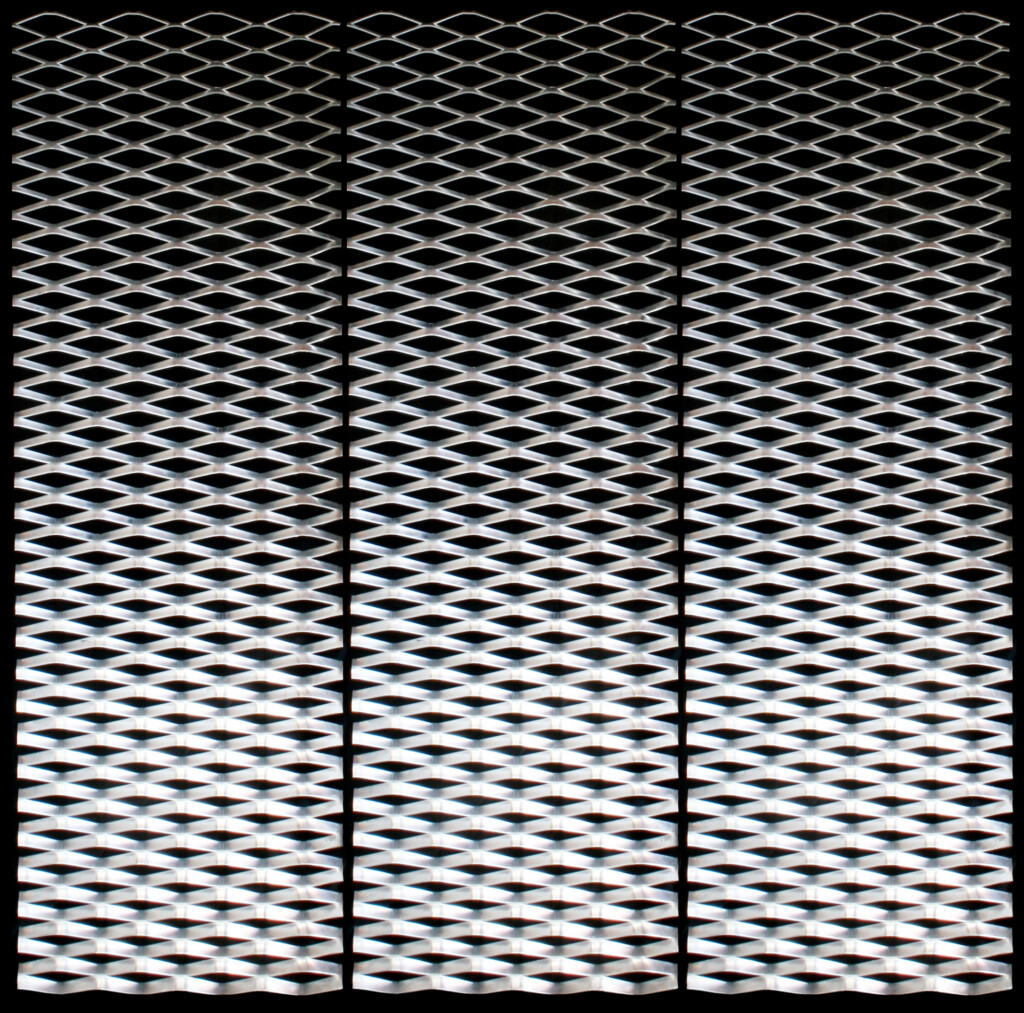

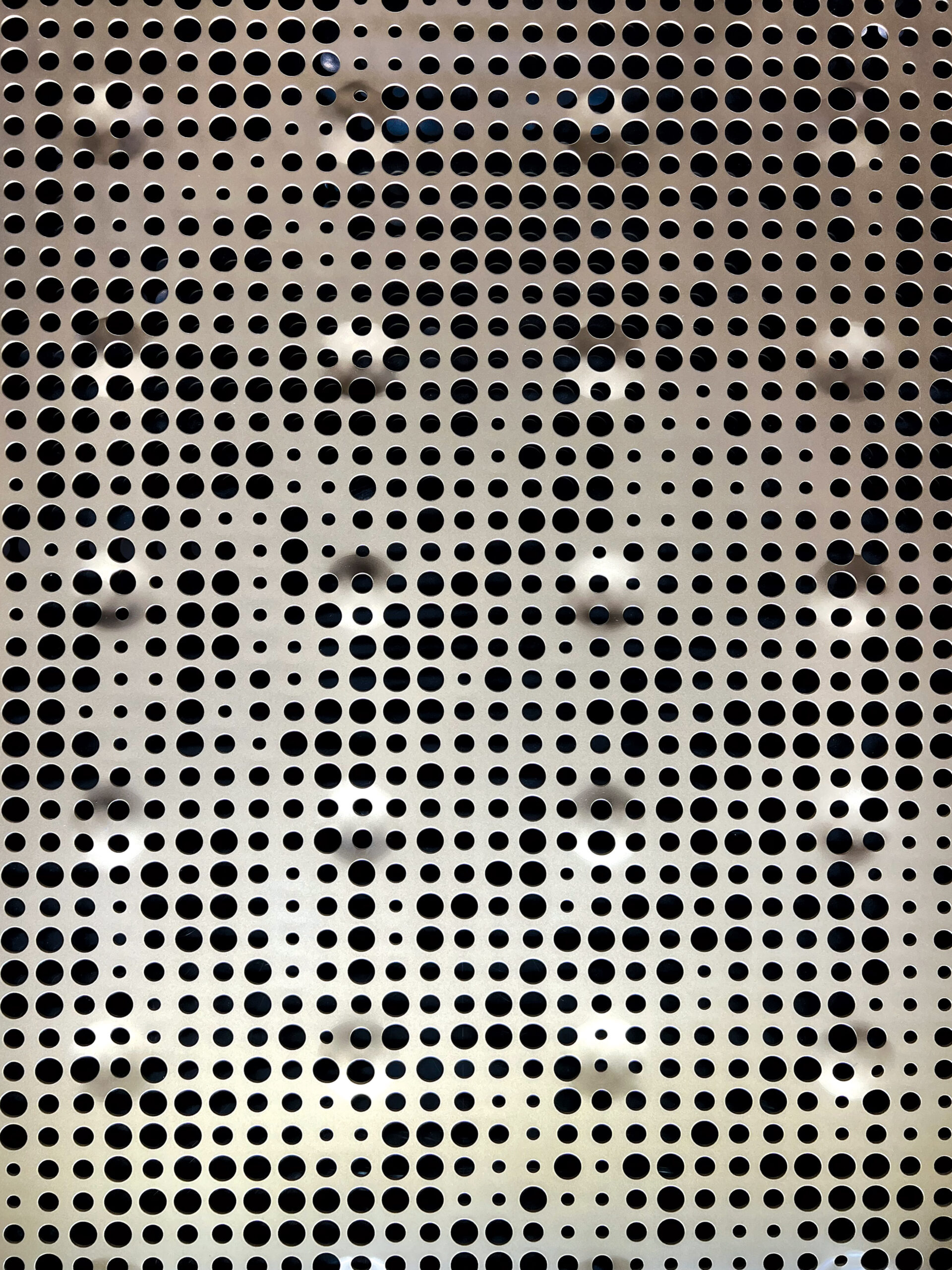

All-Across Perforation Manufacturing

All-across perforation can start with a coil of aluminum or sheets and go through a press with fixed dies that rapidly open and shut, punching the holes as they go.

View common all across patterns:

PROS

- Fast production

- Cost-effective

CONS

- Reduced design flexibility (the holes are the same from line to line)

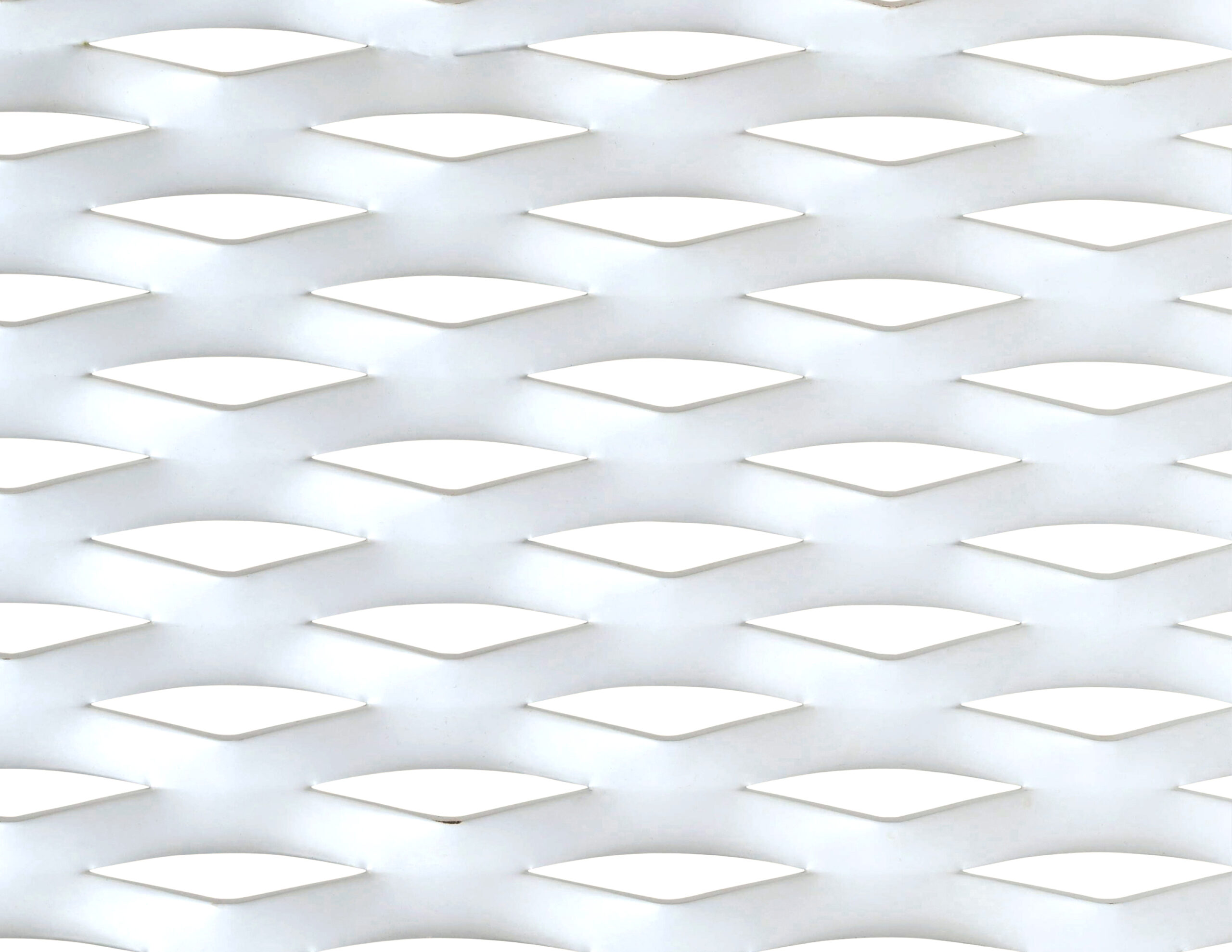

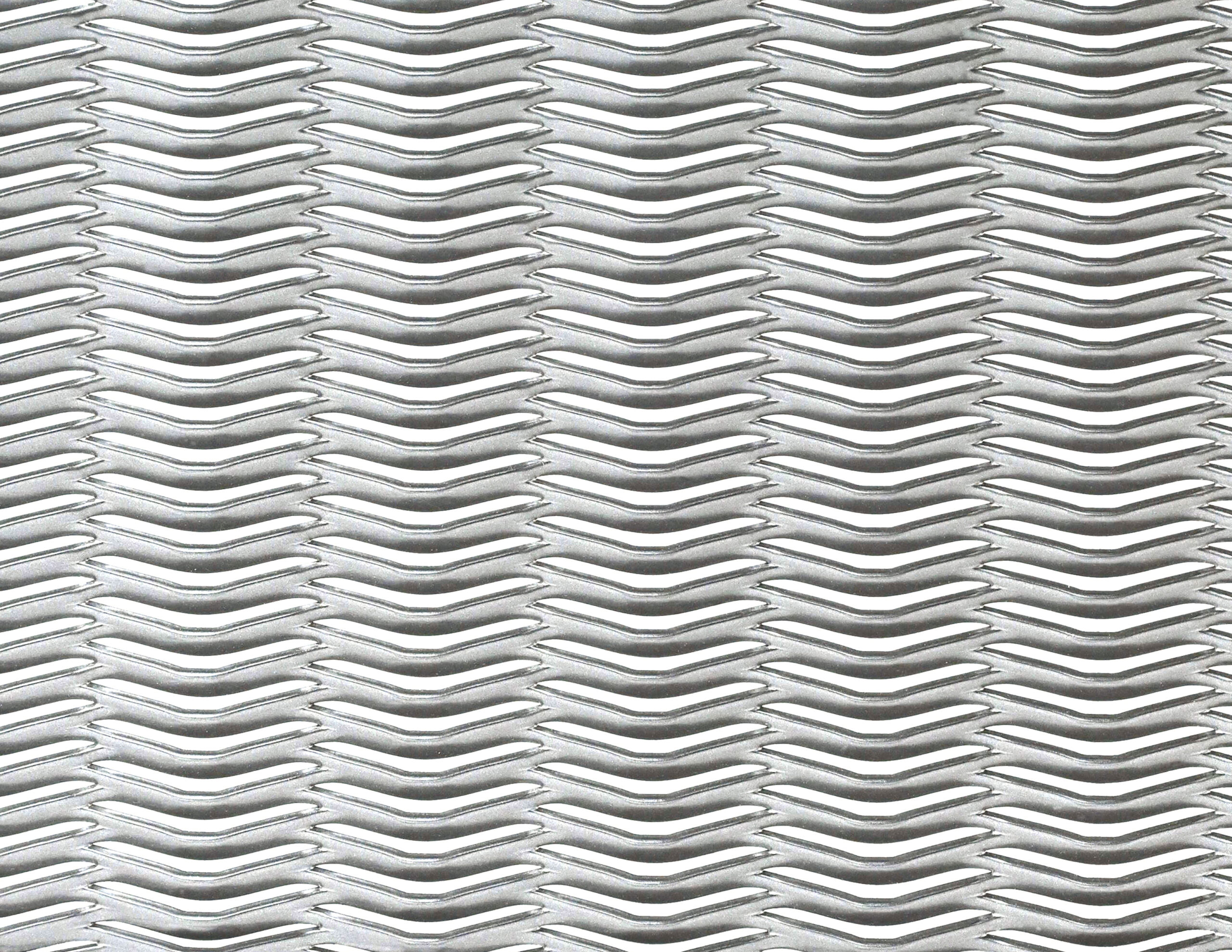

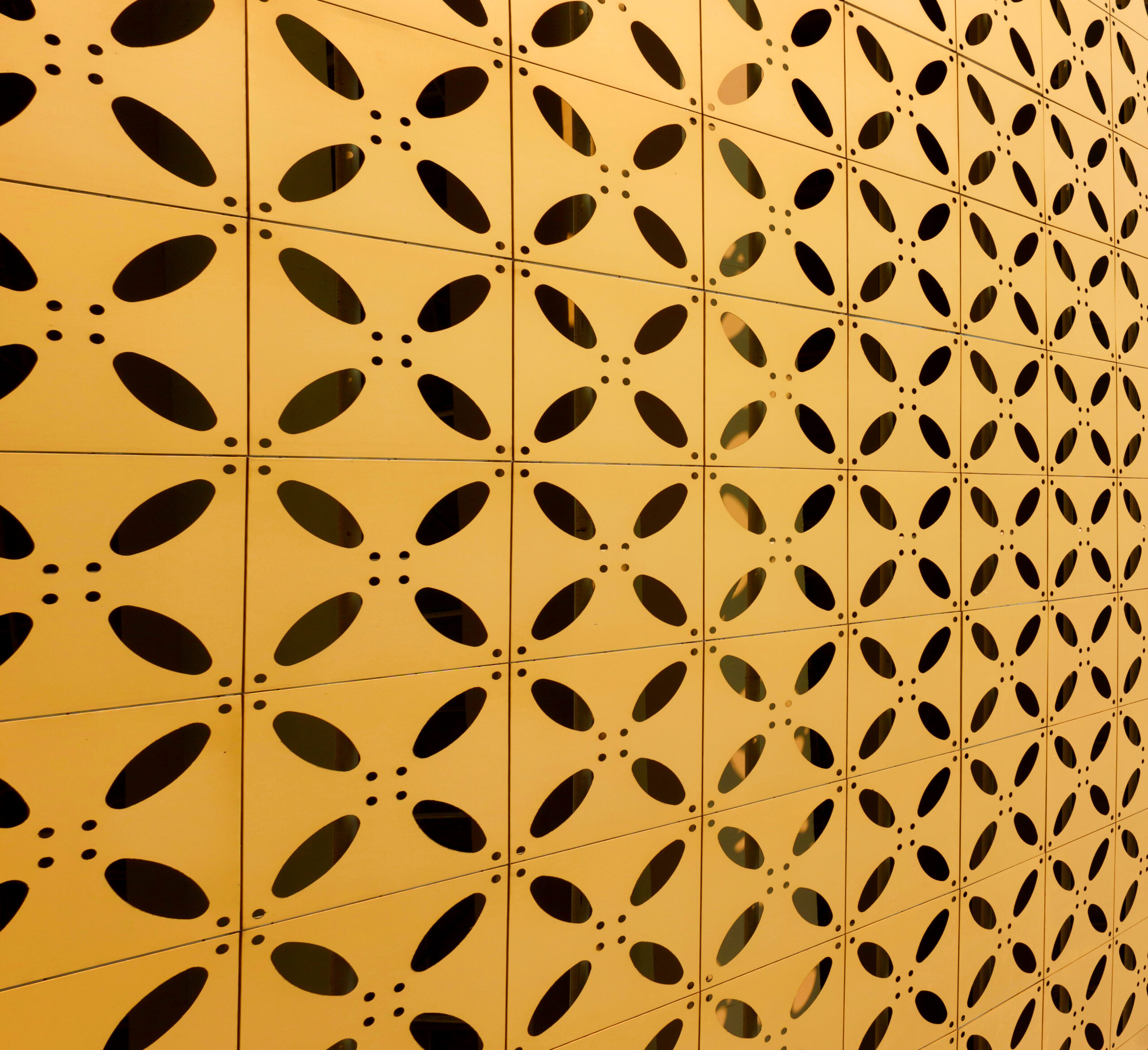

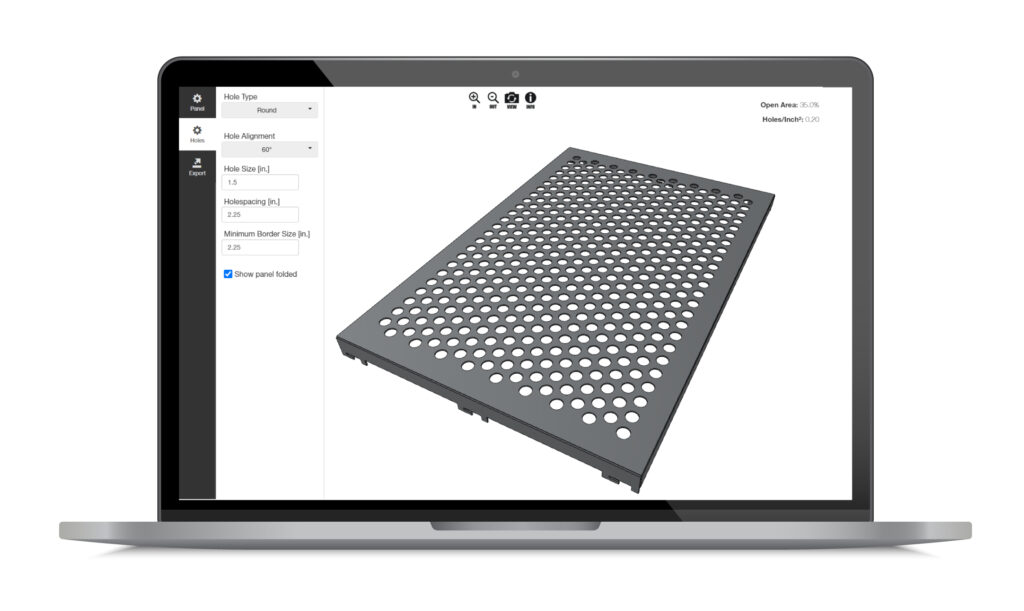

Turret Press, Custom Perforation Manufacturing

Turret Press perforation uses a press with a moving bed and a library of dies it can select for punch and dimple surfaces. The equipment can take in design files and place holes to create unique textures and patterns.

PROS

- High level of flexibility in design

- Dimpling is available

CONS

- Slower manufacturing process

- Slightly higher cost

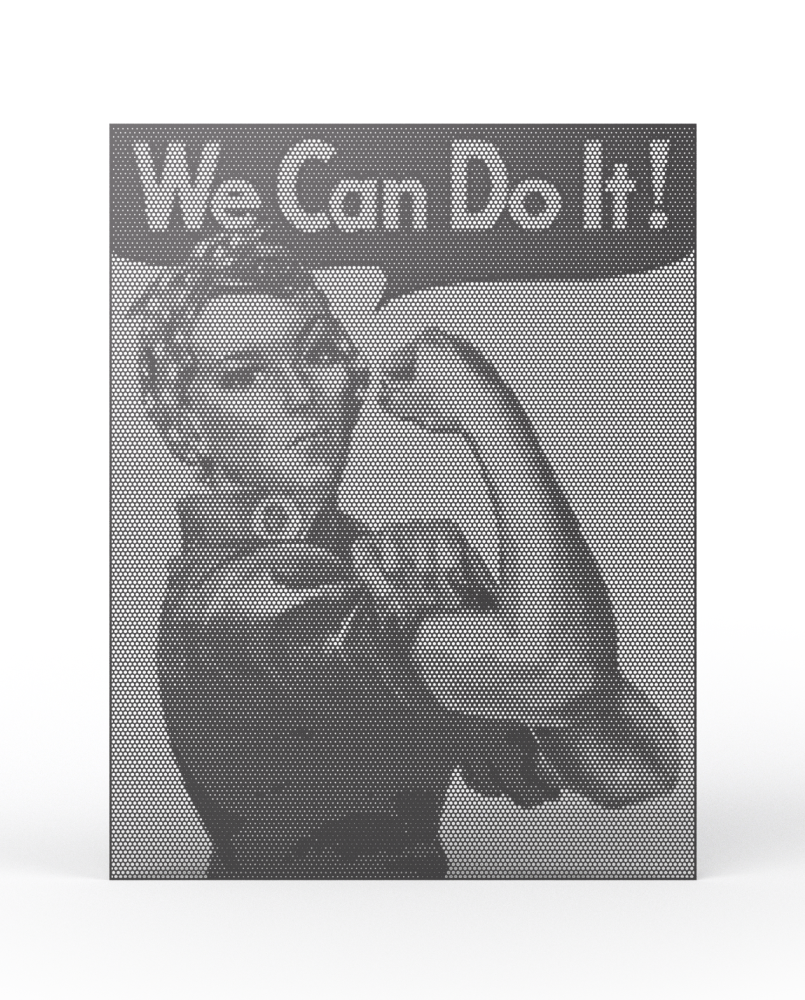

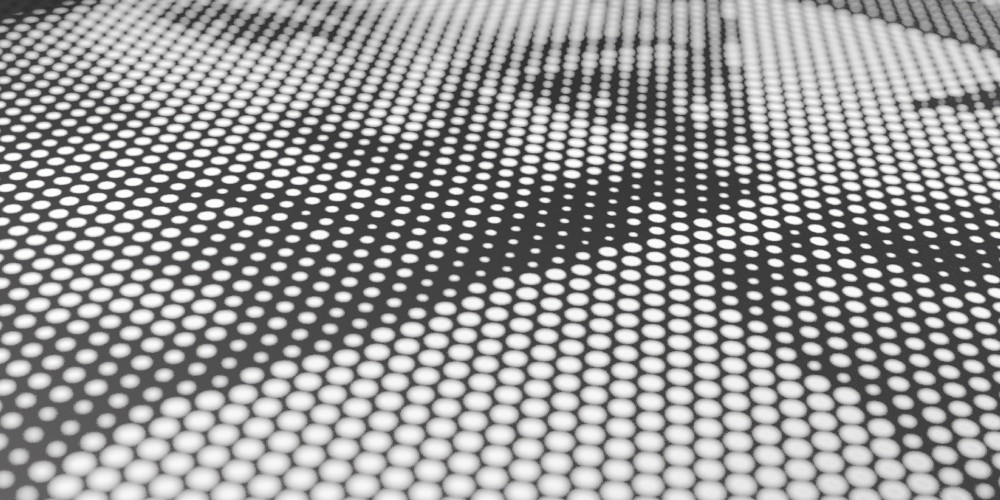

Picture PERFect Perforated Manufacturing

Picture PERFect is an AMICO proprietary process that takes images and converts them into a perforated pattern that a turret press uses to create images in metal using holes. To learn more about how to start a Picture PERFect project, click here.