Advantages of Perforated Metal Solutions in Acoustic Applications

- Many acoustic panels lack the durability needed for outdoor or high-traffic areas. Perforated metal is easy to maintain and can act as a protective barrier to increase the lifespan and performance of acoustic panels.

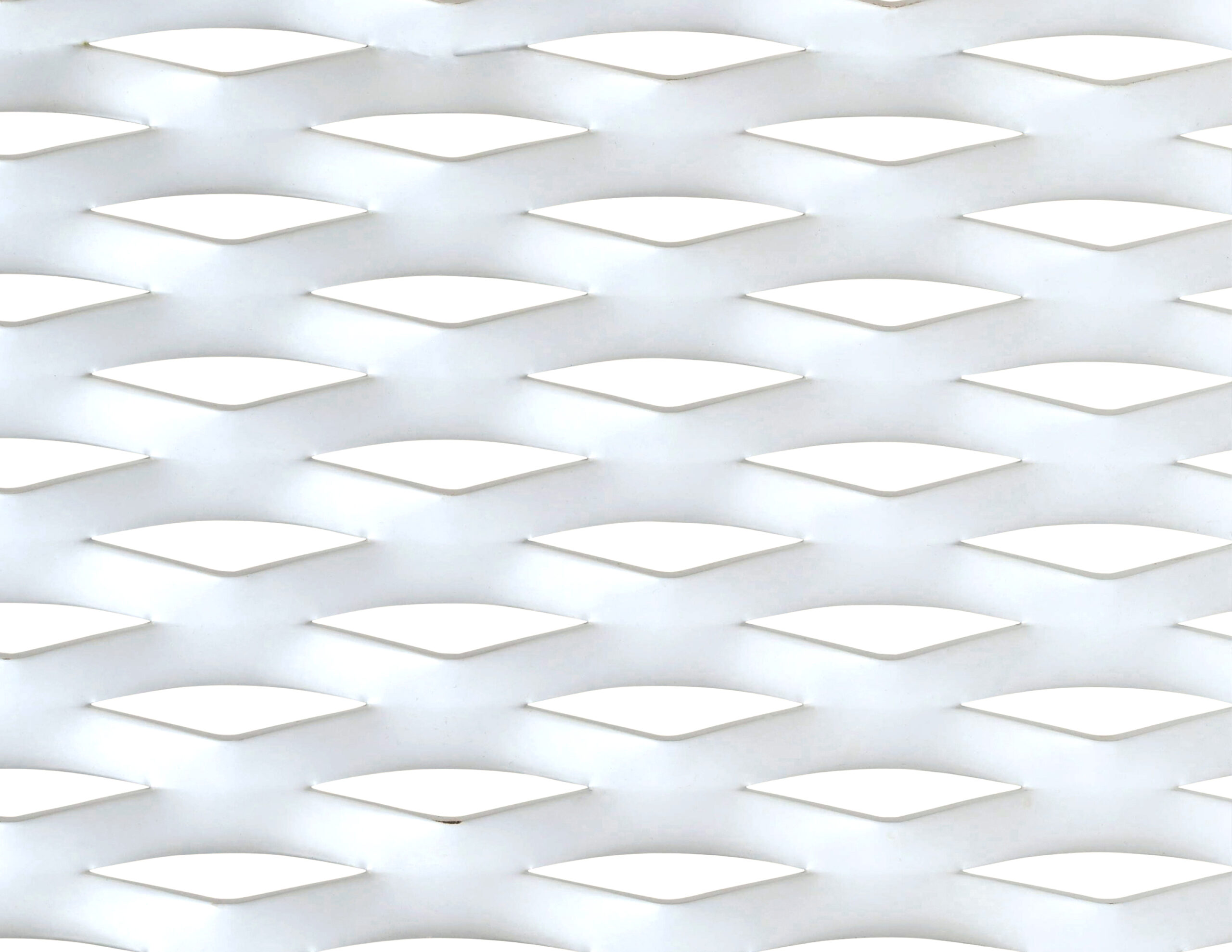

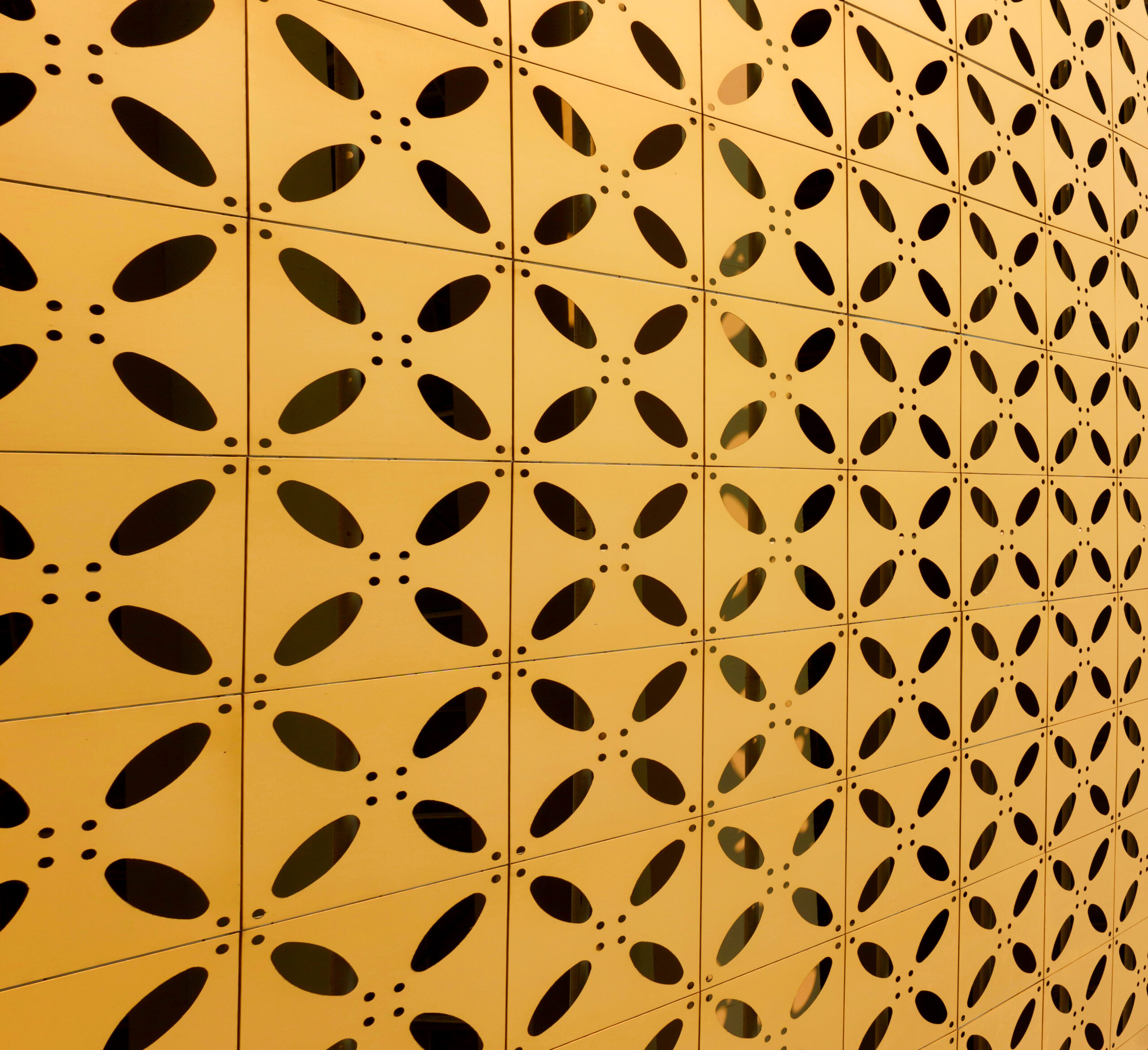

- Perforated holes are easily customized to meet the detailed frequency needs of a given application.

- Aluminum and stainless steel provide aesthetically attractive surfaces to complete your design.

- Perforated metal is easy to form, bend, and shape. This allows the architect to apply the panels in a wide variety of forms to meet design needs.

- Aluminum is excellent for fire safety as it is noncombustible with a 660°C melting point

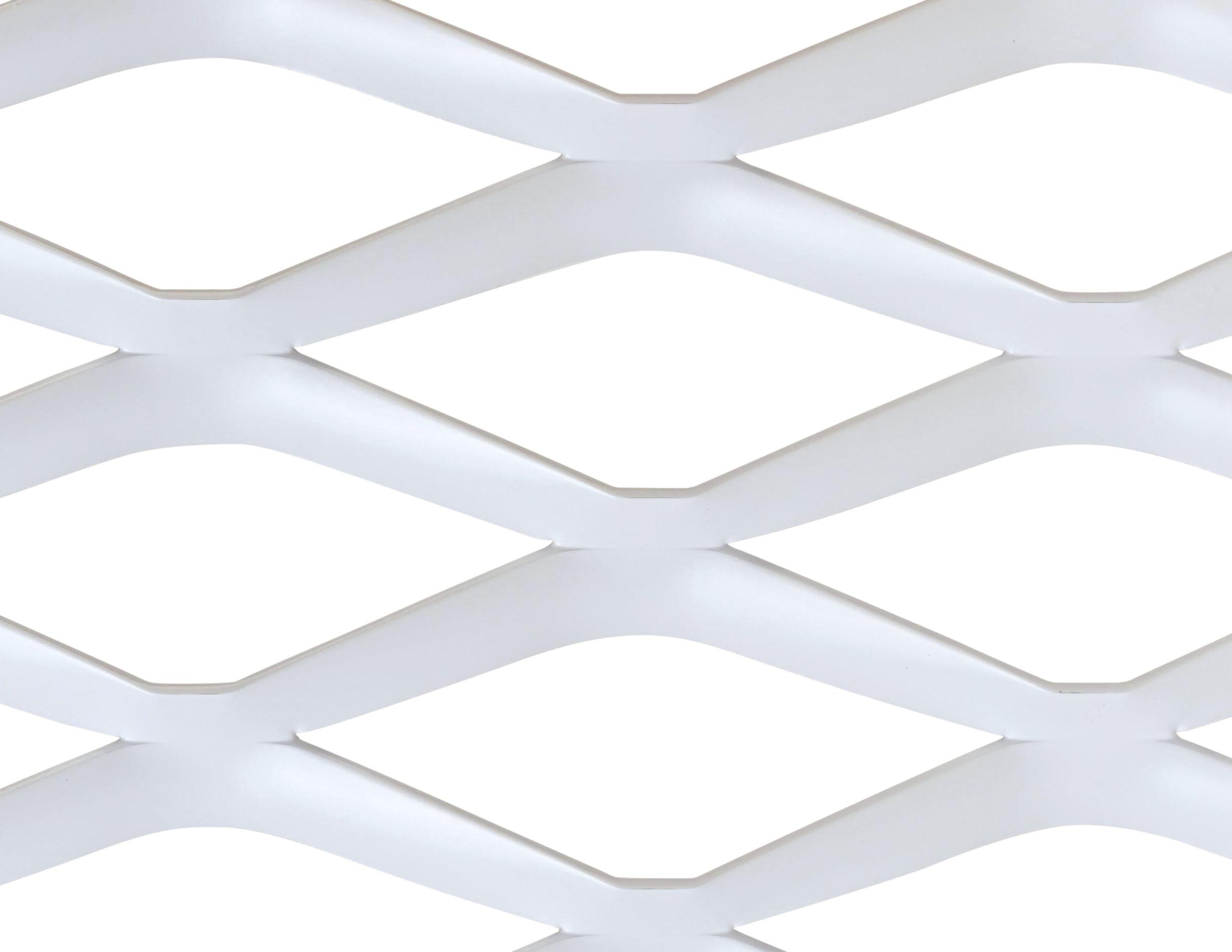

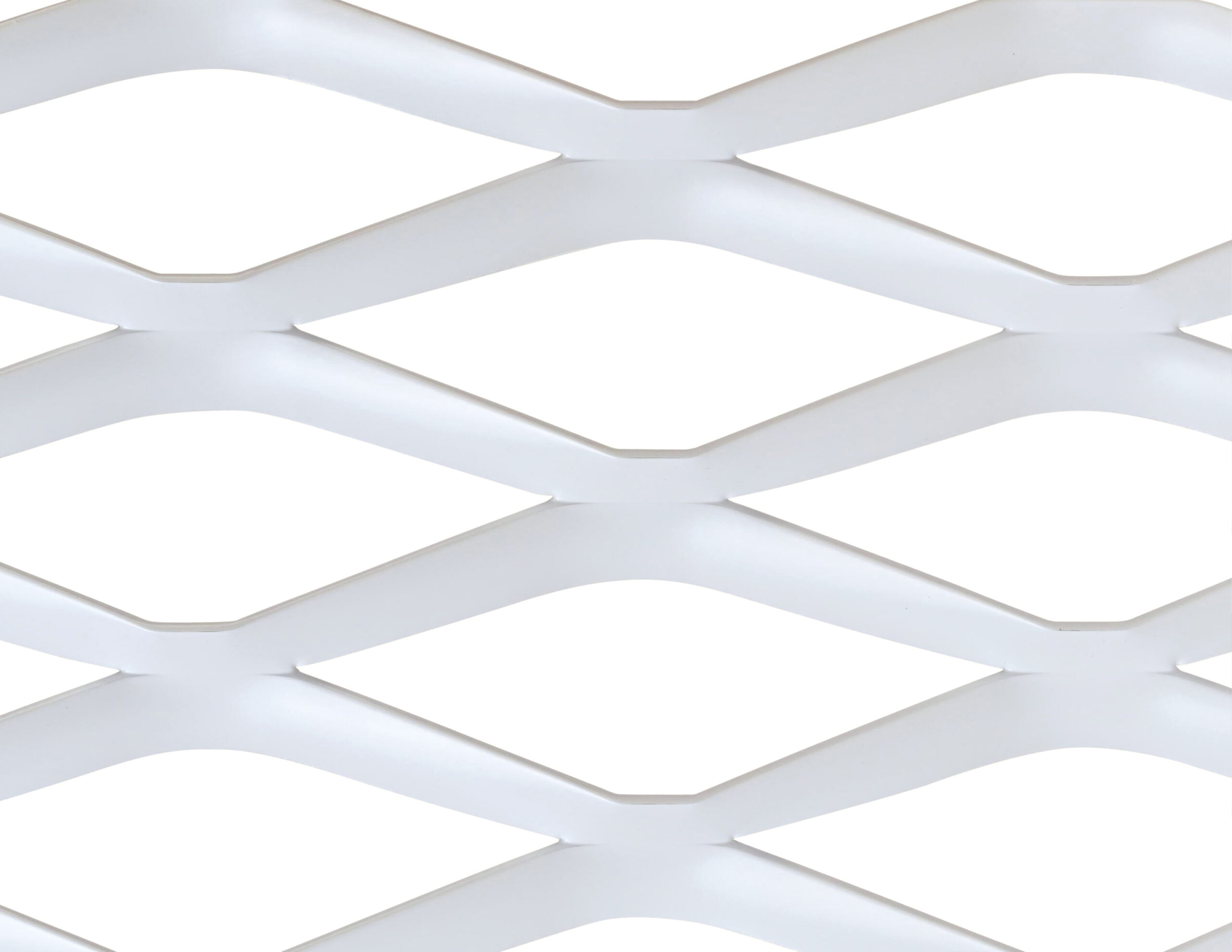

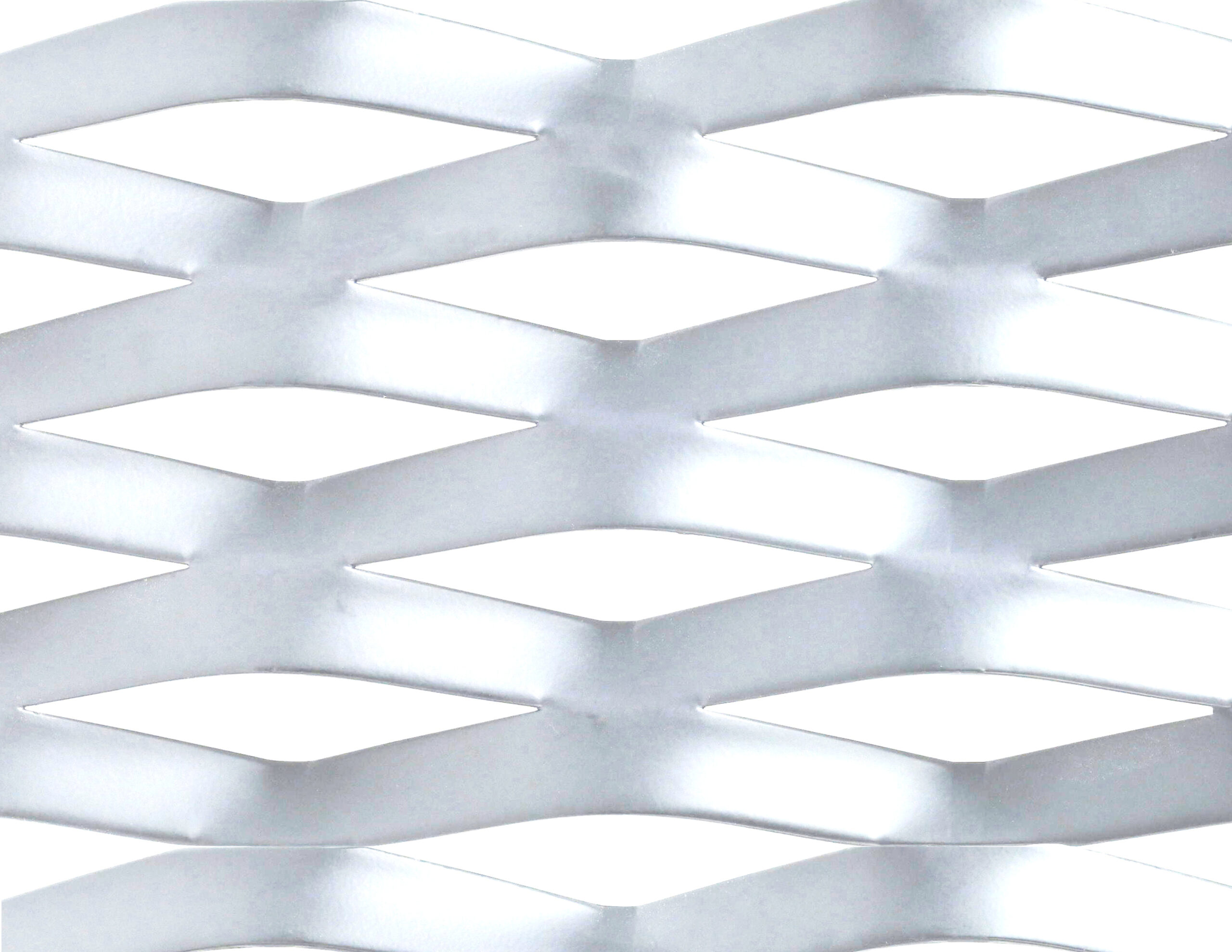

When considering designing with perforated metal for acoustically demanding situations, it can be used to either actively manage frequencies or be an acoustically transparent protective surface for another material. These solutions most frequently utilize aluminum or stainless steel for their lightweight and corrosion-resistant properties.

Acoustically Transparent Perforated Metals

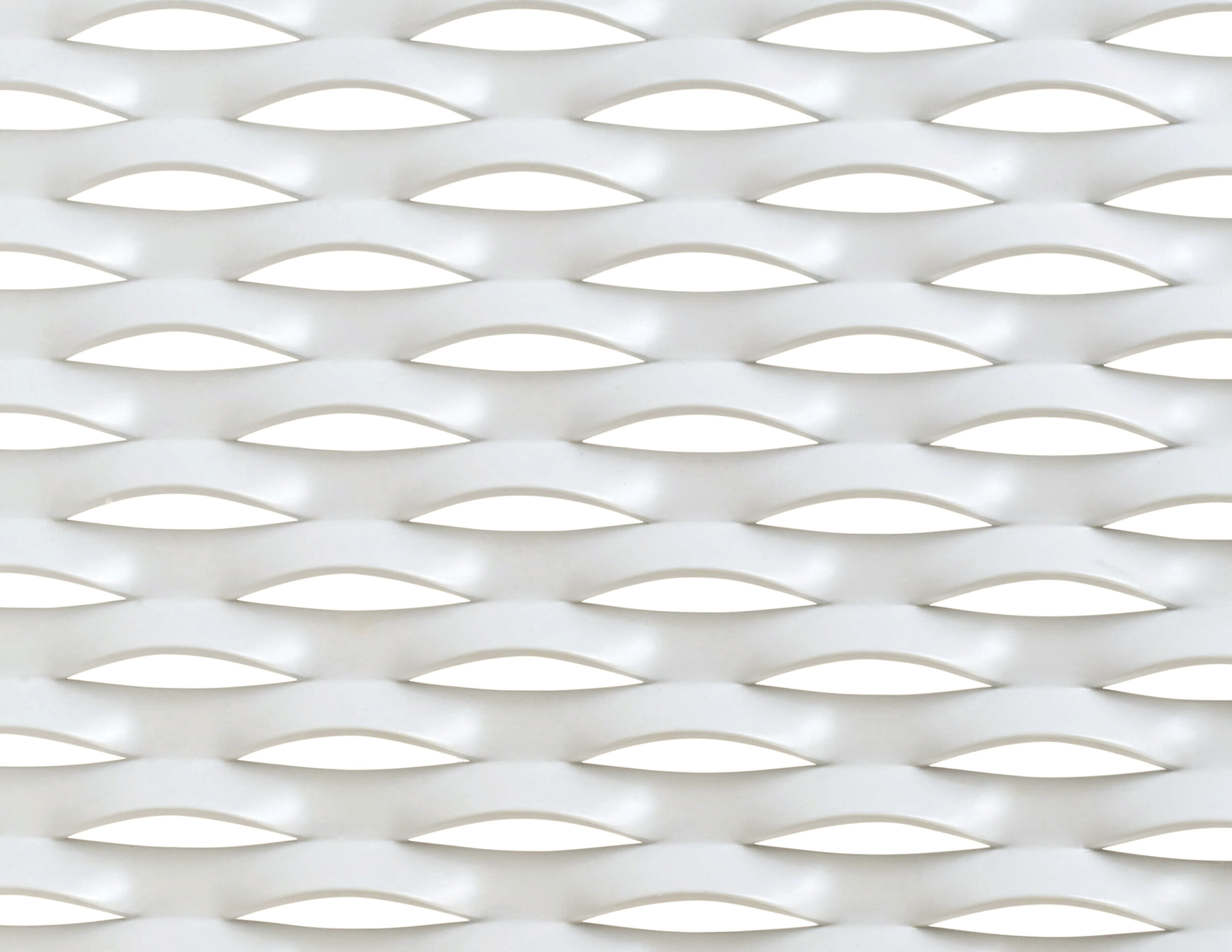

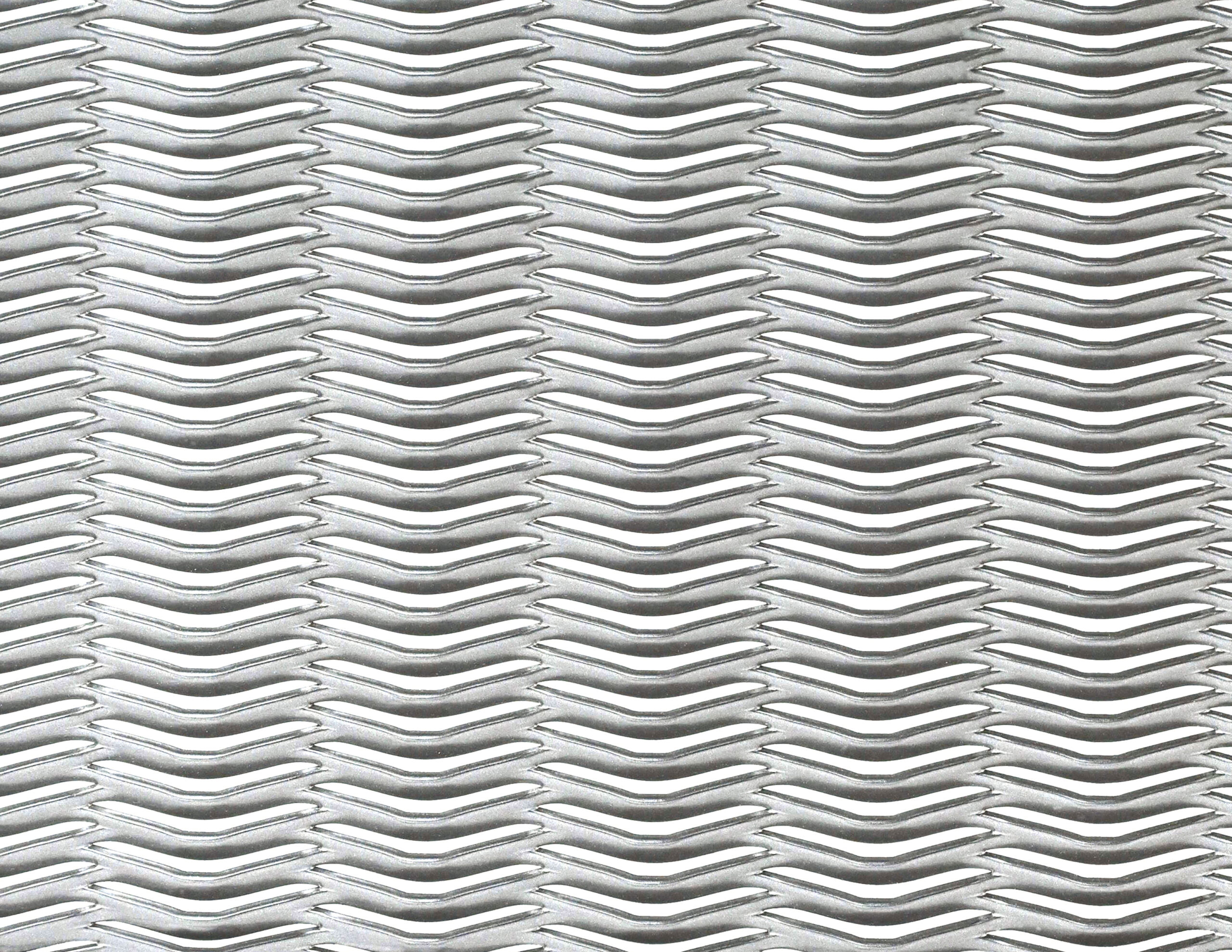

Perforated metal, as an acoustically transparent surface, is often used in high-traffic or outdoor settings where an acoustic tile is added to protect and enhance aesthetics. In these applications, it is essential to have a hole pattern that is small and dense to ensure a maximum number of frequencies pass through the metal and into the backer, where they are either absorbed, reflected, or scattered.

Using Perforated Metals to Actively Manage Frequencies

In applications where the perforated metal manages the frequencies, the holes of the panels interact with a layer of trapped air to concentrate the absorbed sounds into a specific frequency range. This arrangement is best suited for absorbing low-frequency sounds. To achieve the desired result, the perforation pattern, pitch, and thickness of the metal material are also critical and require extensive analysis.

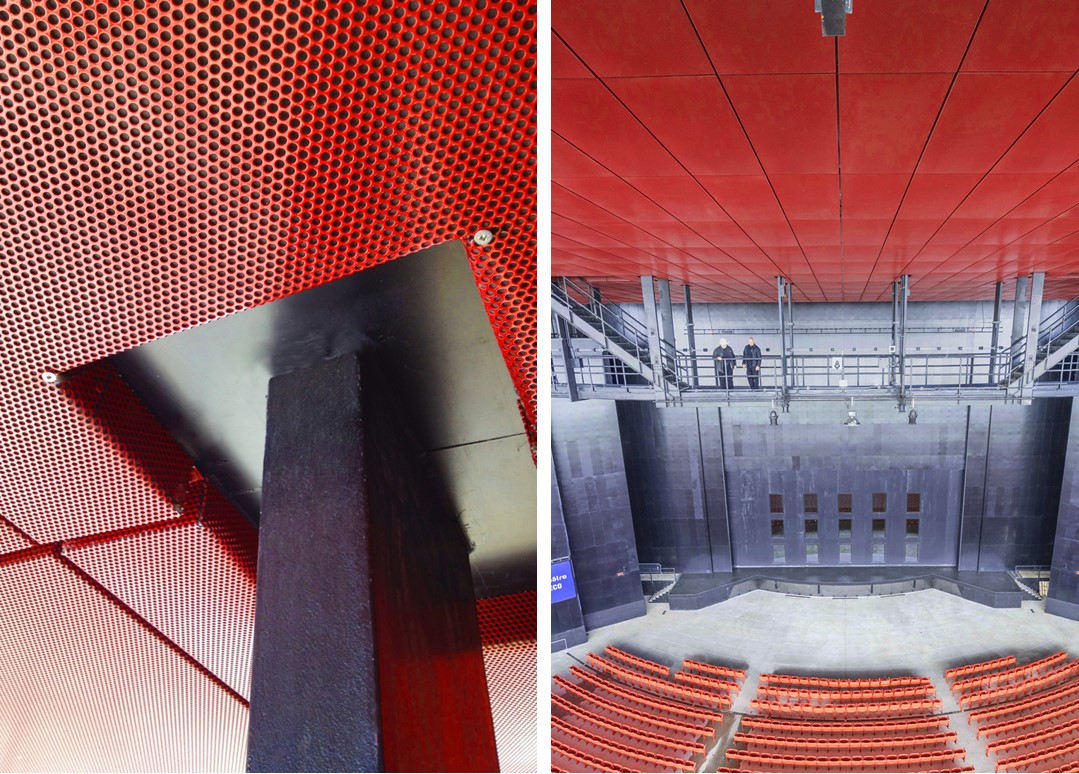

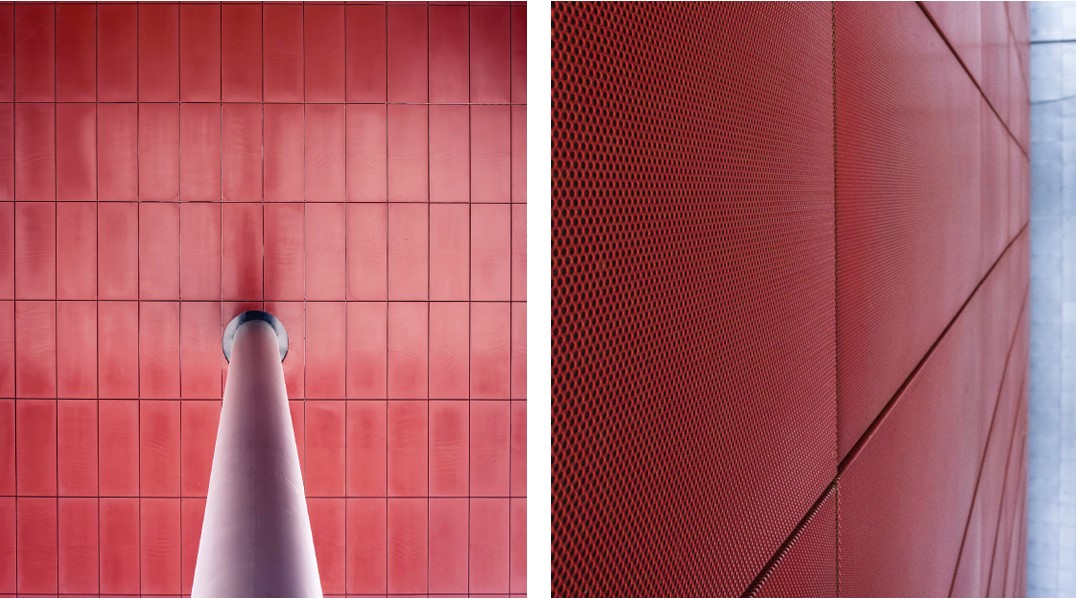

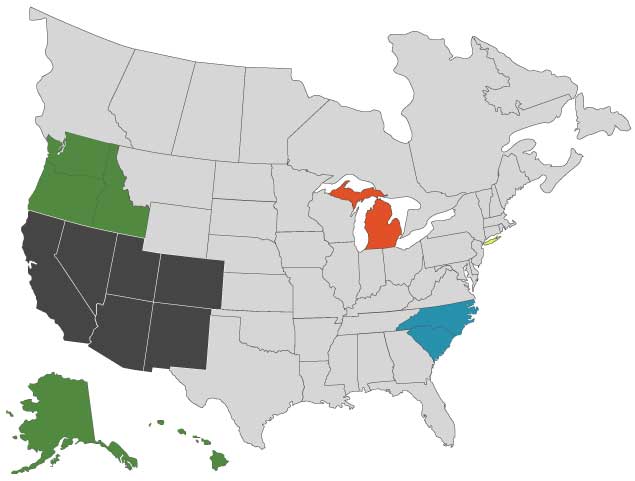

Case Study – Amphithéâtre Cogeco Trois-Rivières, Quebec

The Cogeco Amphitheater is a 9,000-seat open-air amphitheater positioned between two rivers. Without acoustical intervention, the sound would leave the stage and fade quite easily. Octave was hired as the acoustical consultant to project the sound effectively. The strategy adopted was to utilize the lower-level walls and electronics to project and reflect the sound. At the same time, the monumental, iconic red roofline would then dampen and absorb the sound to prevent echoing. AMICO perforated aluminum was used as an acoustically transparent protective façade surrounding Rockwool fiberglass acoustic panels. The aluminum was able to benefit the project because it could protect and extend the life of the acoustic panels in the harsh, humid environment that varied from -30°C to 30°C, as well as take on color to create the exemplary red structural form that architect Atelier Paul Laurendeau so keenly designed.

Leave a Reply