Expanded metal manufacturing has been a well-established process for many years; however, there are important details in the manufacturing process that ensure the expanded mesh meets the quality standards for architectural applications. Here are a few questions you need to ask your expanded metal partner to ensure a quality installation:

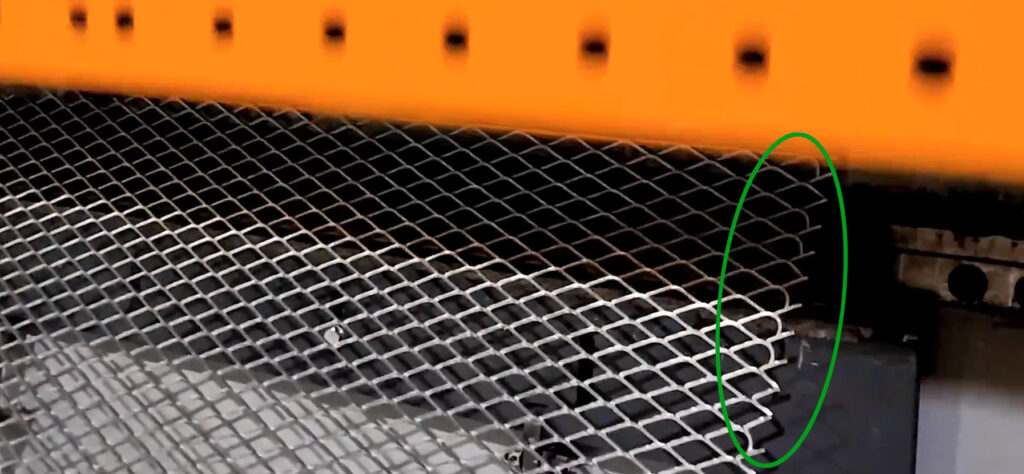

Do you trim the outside diamond on the expanded mesh sheet?

The expanded mesh manufacturing process usually produces outer diamonds that are slightly distorted. Depending on the expanded mesh style, this may be more prominent in some designs than others. High-quality manufacturers will go to the extent of trimming off the outermost diamond to ensure the highest level of visual continuity in the surface you specify.

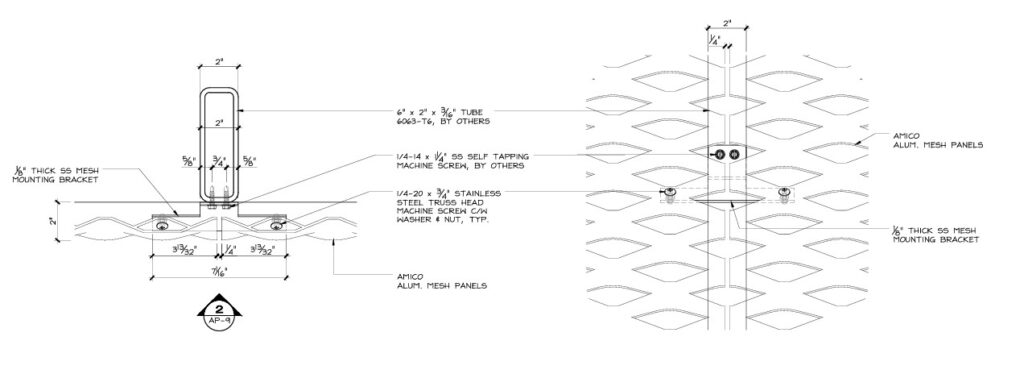

Do you pre-drill attachment holes for attachment brackets?

Some manufacturers do not pre-drill the holes needed to provide attachment points to the structure. While this saves them money, it causes considerable strain on the job site.

- It means that the installer must know and plan exactly where they need to drill or place self-tapping screws.

- The lack of pre-drilled holes means that any holes created on the job site after powder coating will result in exposed, unfinished edges.

- It assumes the installer can consistently hit the center of the knuckle in the expanded mesh. They could miss making the installation lack uniformity, or a screw may ‘walk’ on them just a little bit, causing the powder-coated surface to be marred and need repair.

- All this results in hundreds of small decisions being made on the job site, creating uncertainty, increasing the skill demand on the installer, and slowing down the installation process.

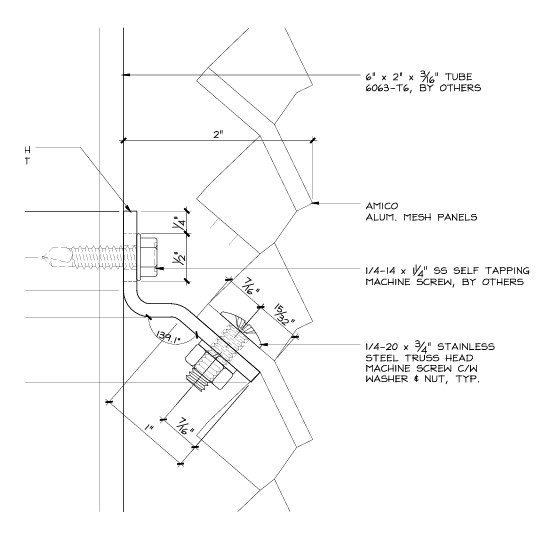

Do you supply angled brackets for installation?

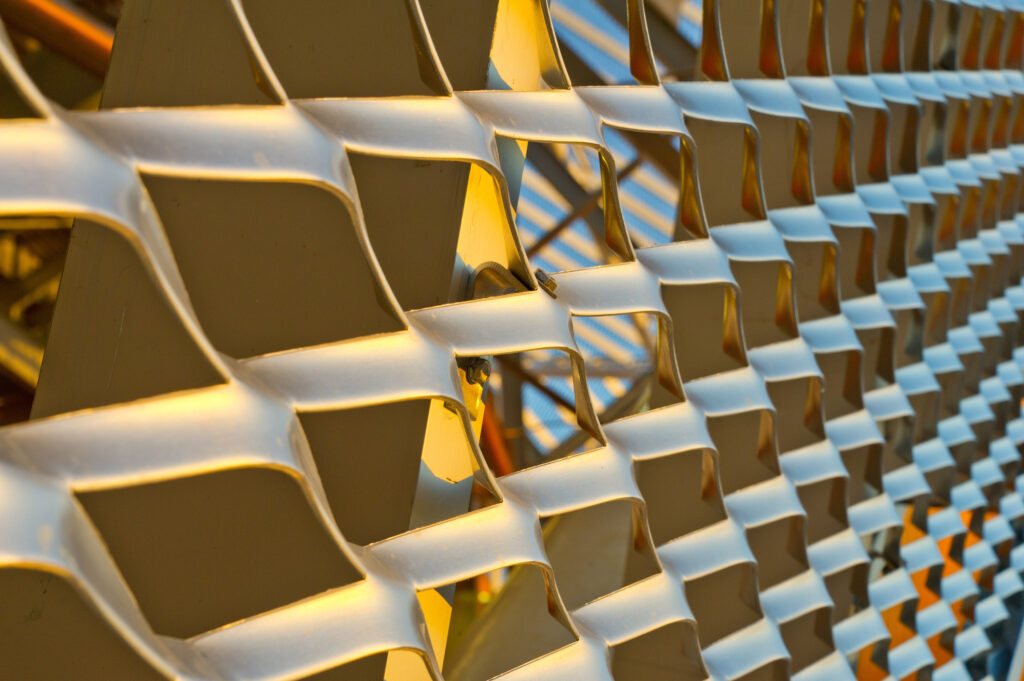

Many expanded mesh suppliers will submit a low bid by not including attachment brackets. These types of installations will appear low-quality because the strands and knuckles that are supposed to be angled will flatten as screws pull the mesh and the subsurface together, creating unsightly anomalies in your surface that you designed to be uniform.

If you provide angled brackets, when in the process do you finalize their design?

There is a small degree of variability in the angle of a stand of expanded mesh, especially those meshes with larger strands and larger diamond openings. To ensure the highest quality fit with the most surface continuity, creating the run of mesh for your project should be done first, so the exact angle of the strand can be verified and the angle of the bracket can be accurately determined.

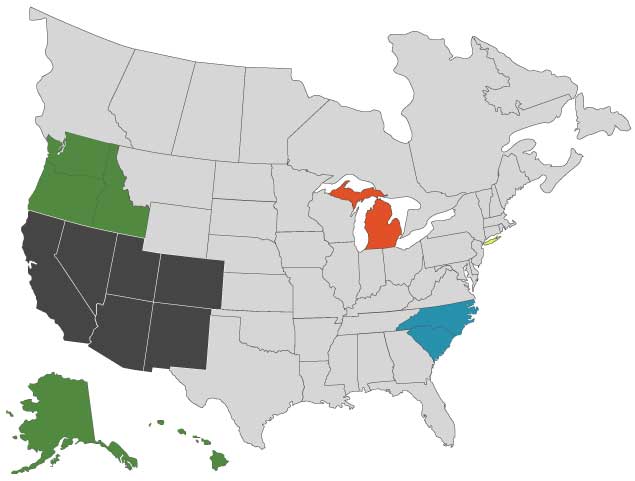

How do you ensure the strands will align from panel to panel?

Strand alignment can be challenging, and processing the panel after production is critical. First, the panel needs to be checked for squareness and trimmed appropriately to ensure uniformity; otherwise, it must be rejected and recycled.

Next, as the panel is planned and designed, the exact size needs to be carefully planned. If there is going to be a 1/8″ gap between the panels, this means that to maintain a perfect diamond flow from one panel to the next, an extra 1/16″ needs to be removed from each side of the panel. Lastly, well-maintained equipment will ensure tolerances are within range, creating perfect visual alignment.

Click here to see some further common expanded mesh details that will impact your design process.