An extremely common question we get asked at AMICO is…

What should the architect specify behind the expanded mesh facade?

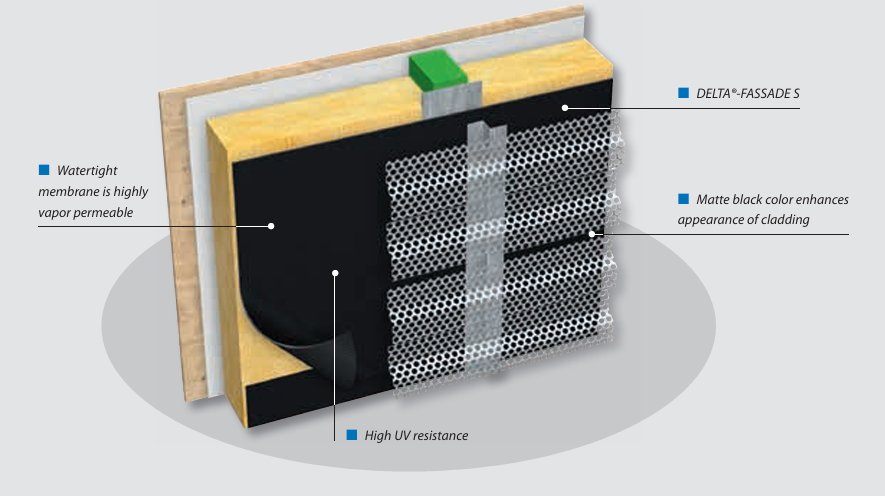

Because all forms of expanded mesh are open to some degree, the surface behind the mesh needs to be water-tight to protect the insulation and prevent water from getting trapped behind the wall.

The question then comes: how do you implement an expanded mesh facade without having to pay for two facades, thereby breaking the budget?

The most cost-effective way to achieve an expanded mesh facade is with an open joint UV and water-resistant open joint backer. AMICO has been working specifically with Dorken to certify their Delta Fassade S barrier as an approved backer to our expanded meshes that have less than 50% open area. The Delta Fassade product is a matte black polyester substrate with acrylic coating that will not compromise the appearance of the expanded mesh installation.

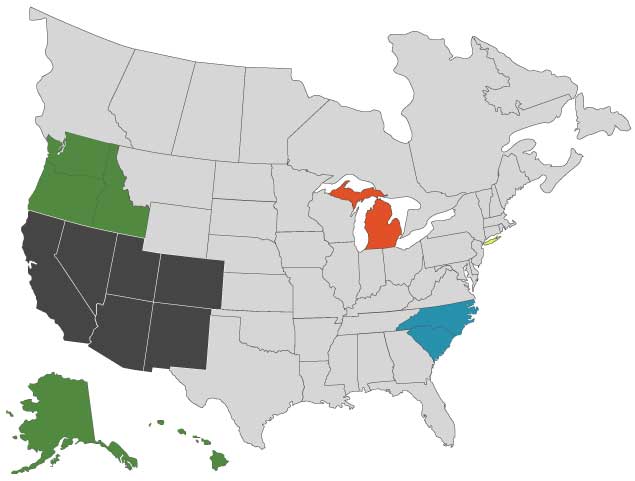

This material is also NFPA 285 compliant and approved under the International Building Code and the International Residential Code, ICC ESR-2932.

Why is this combination of products important?

- Opens up opportunities for lower-budget projects

- Offers value engineering options

- Lowers overall project cost

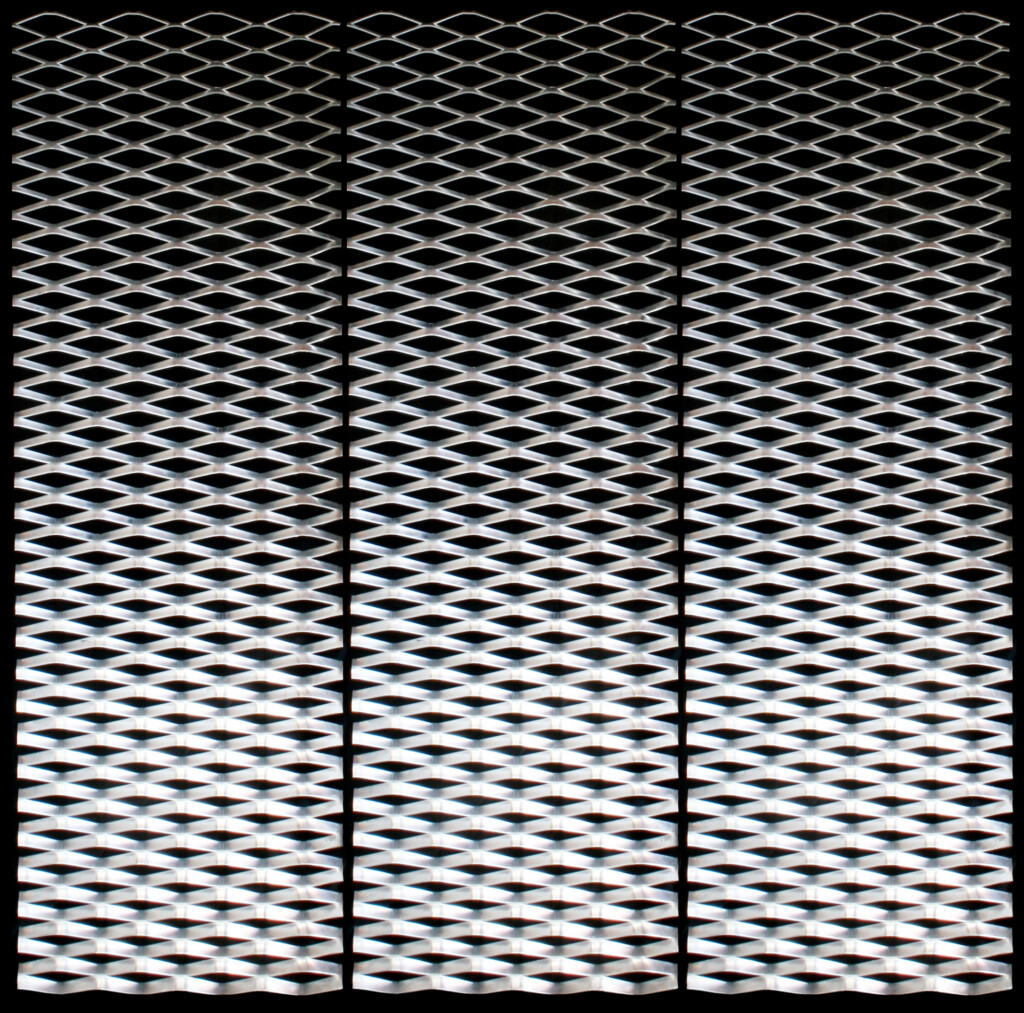

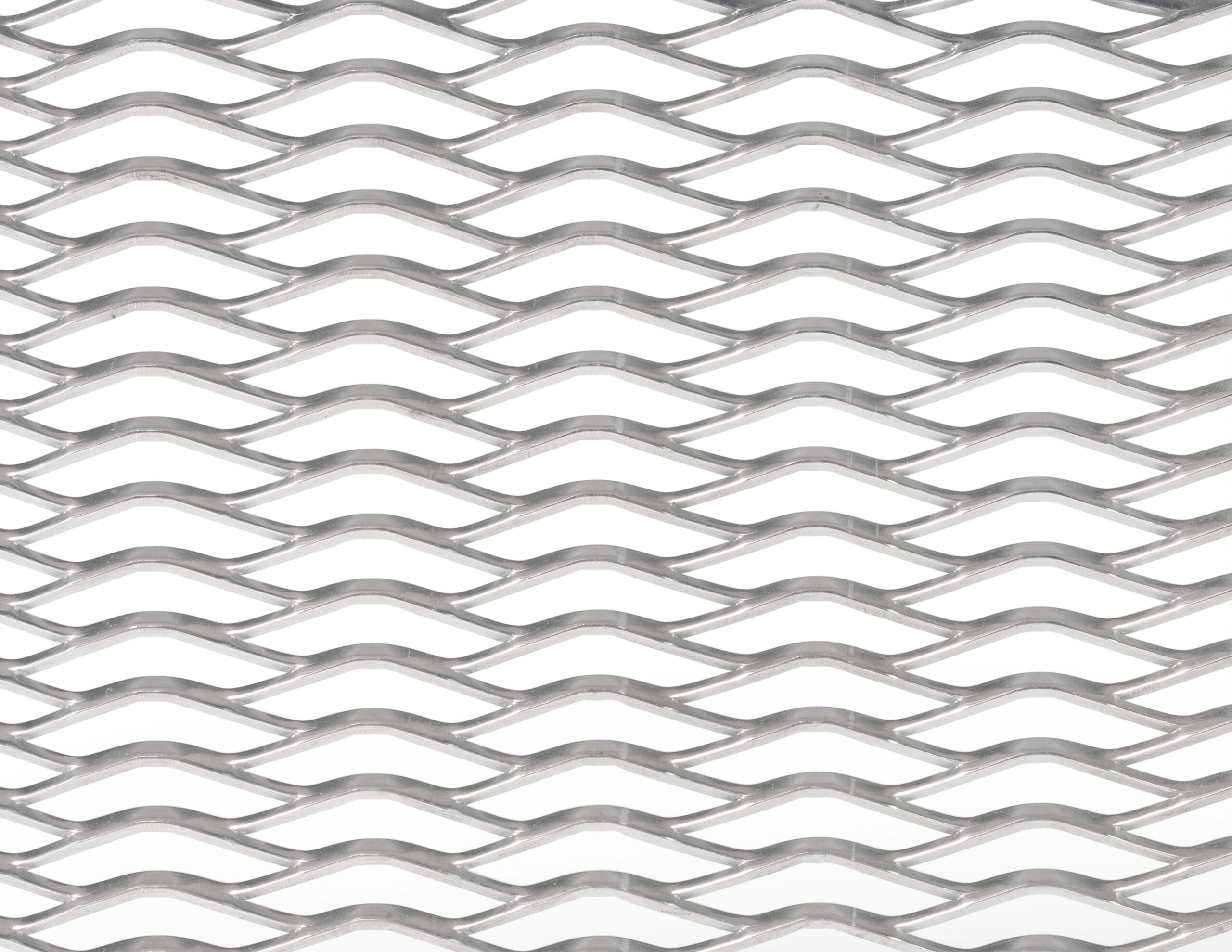

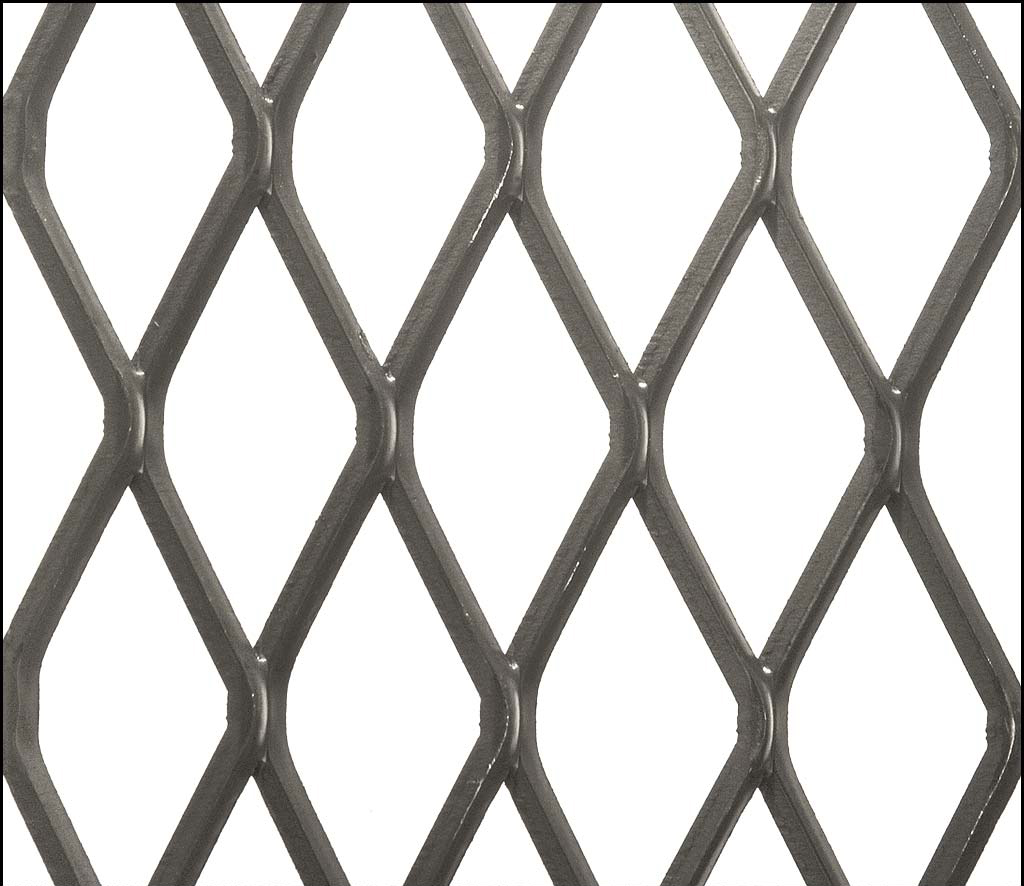

AMICO Products that are approved to work with Delta Fassade Products include:

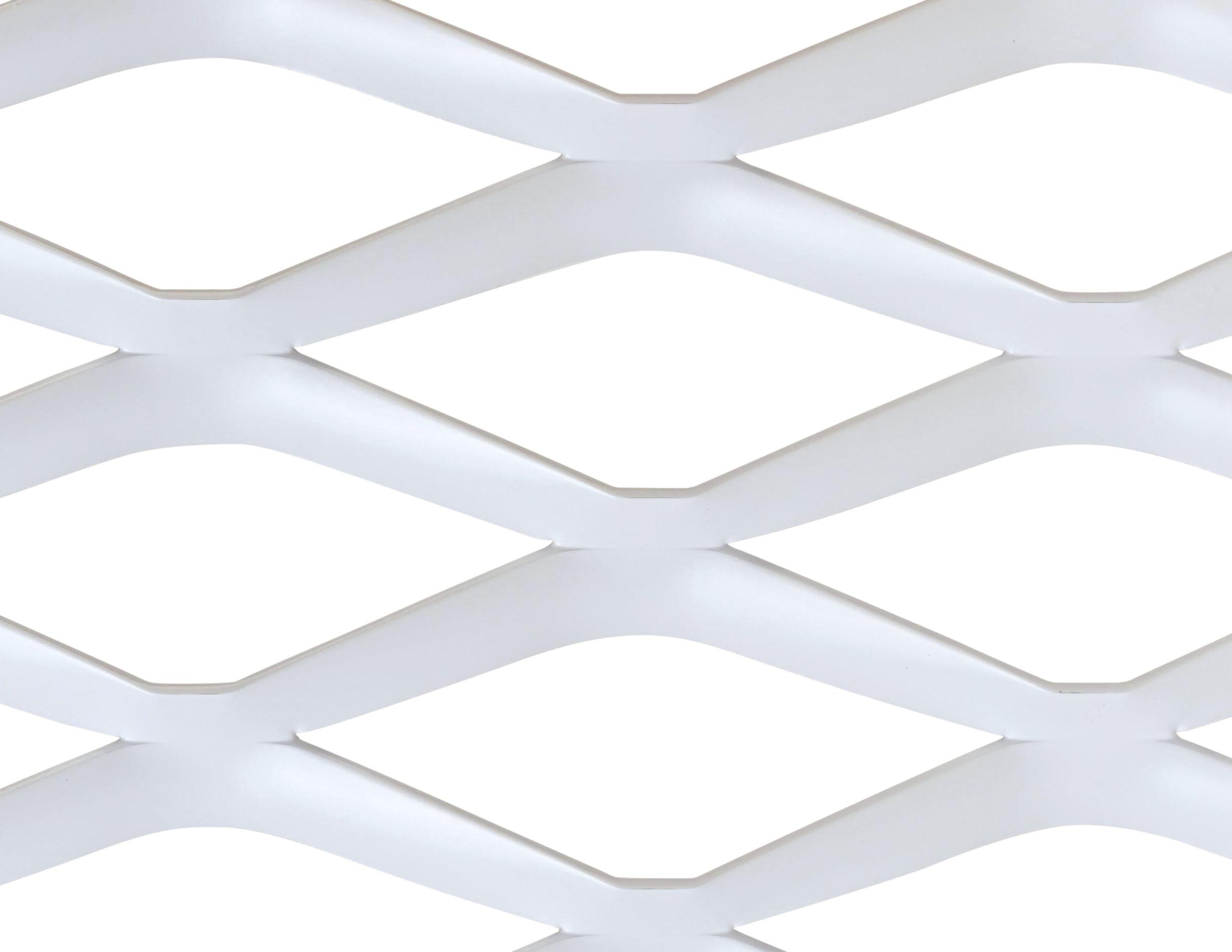

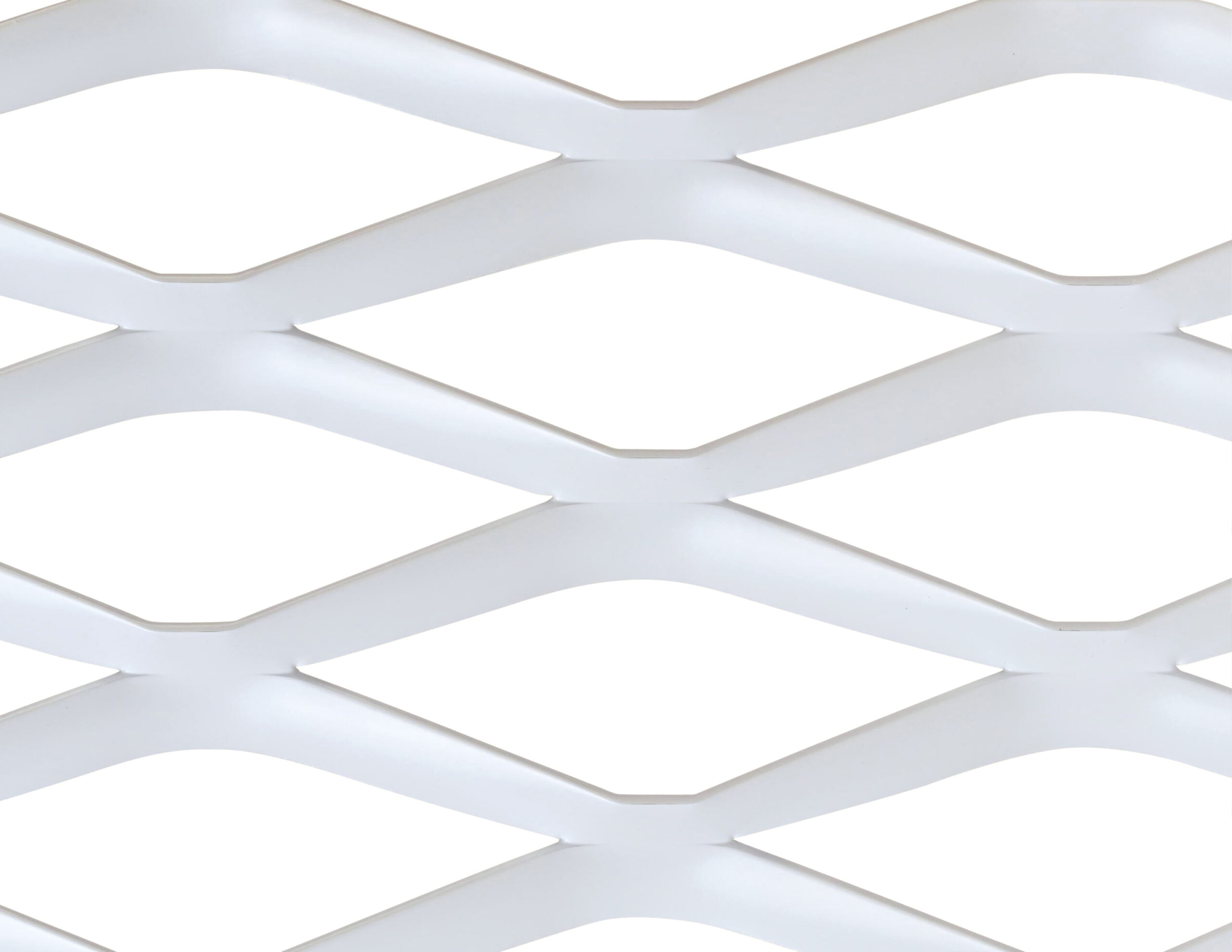

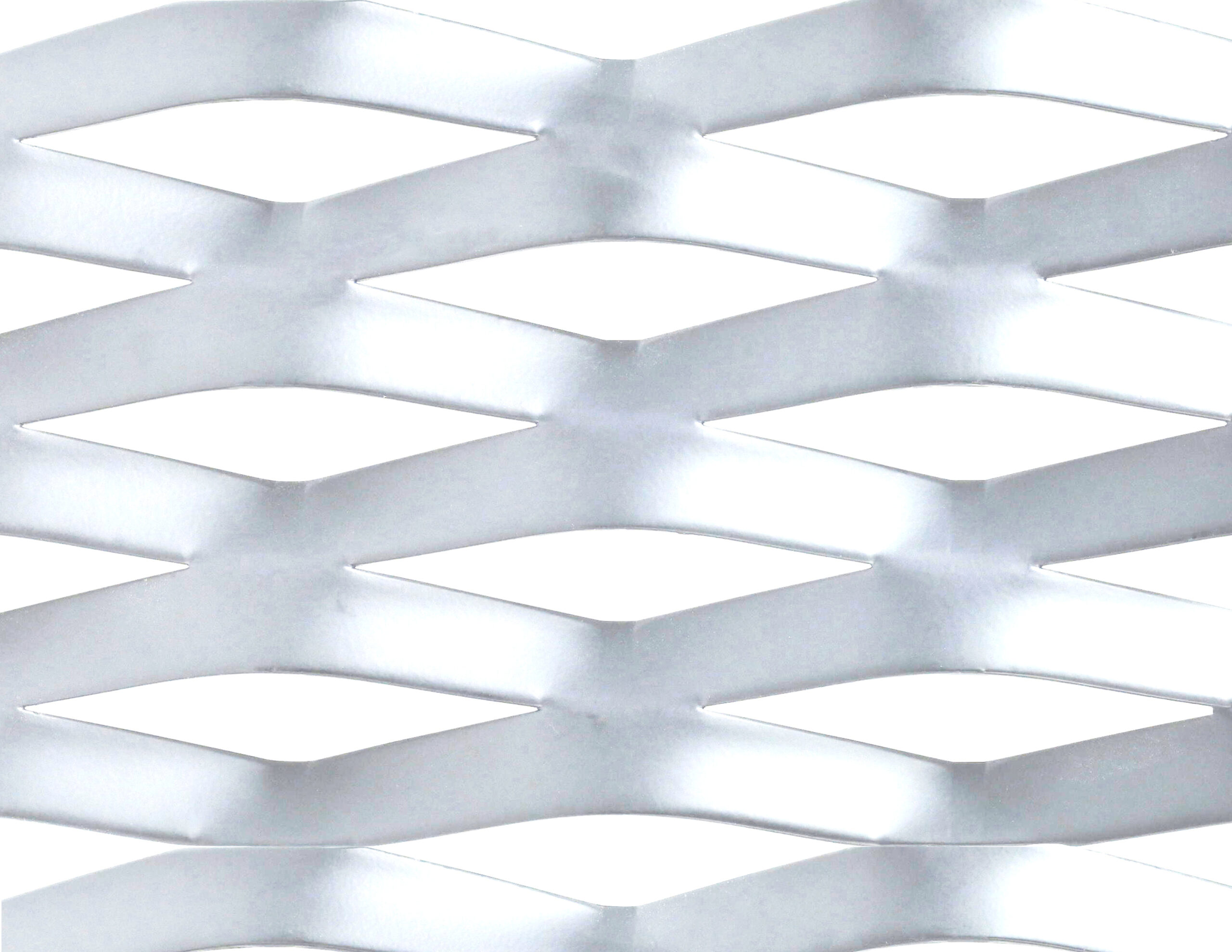

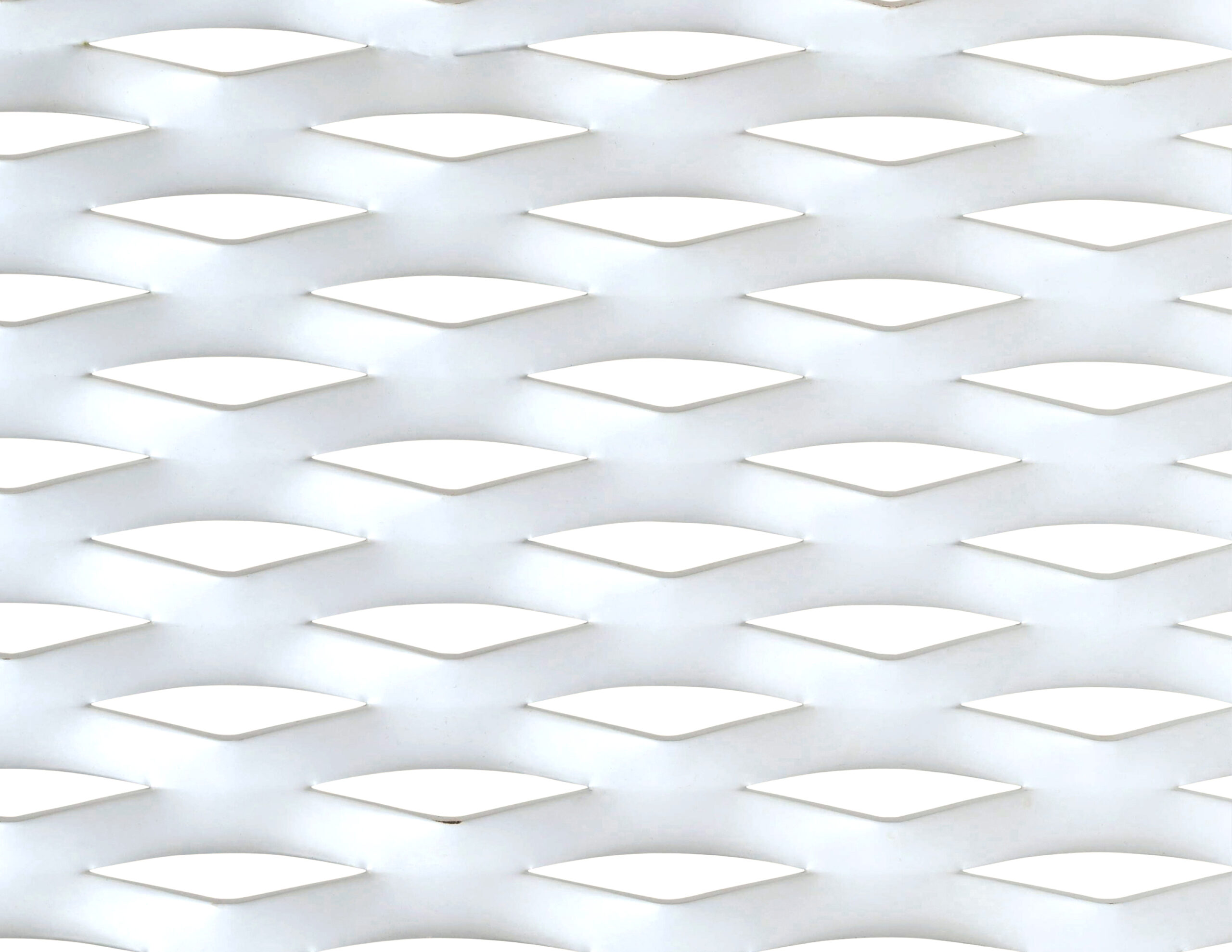

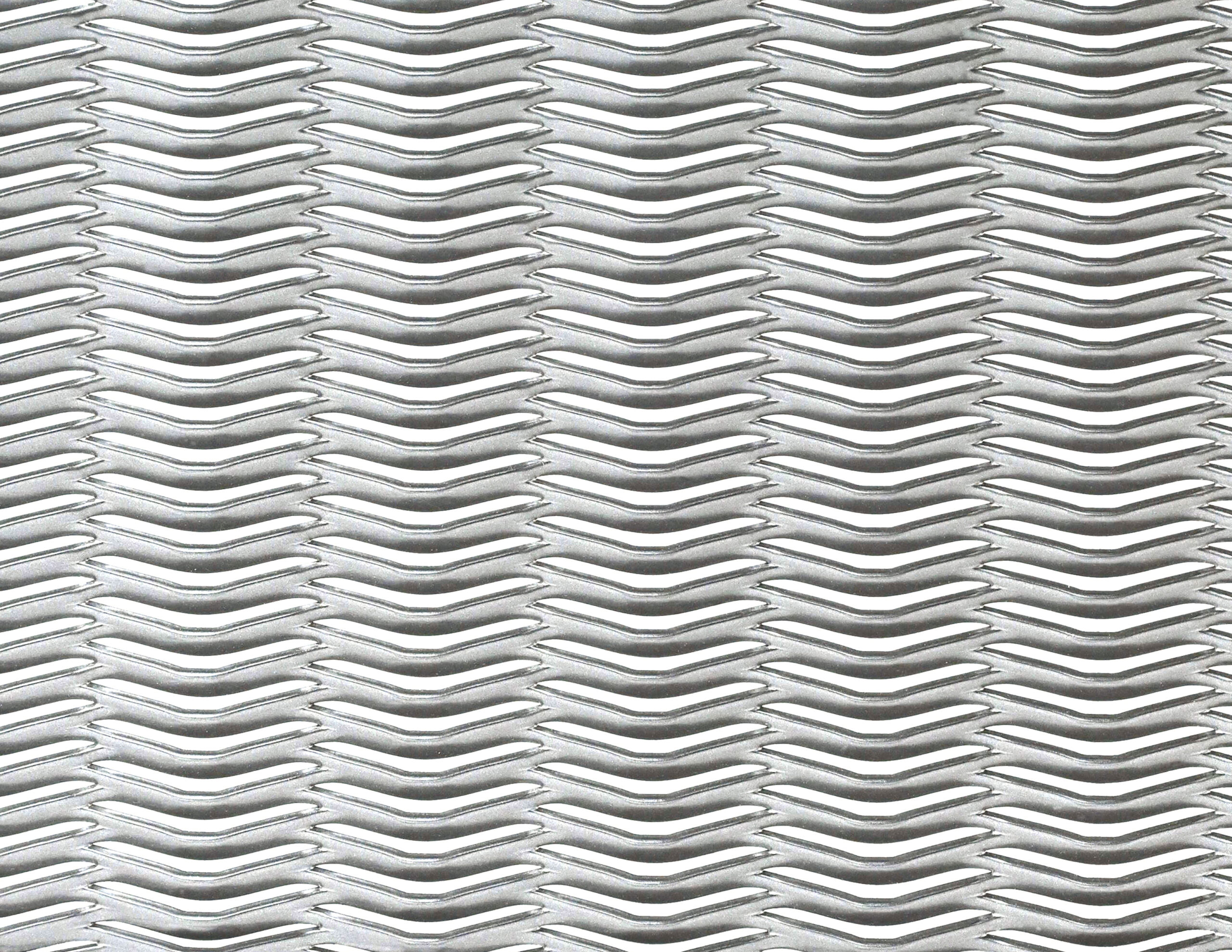

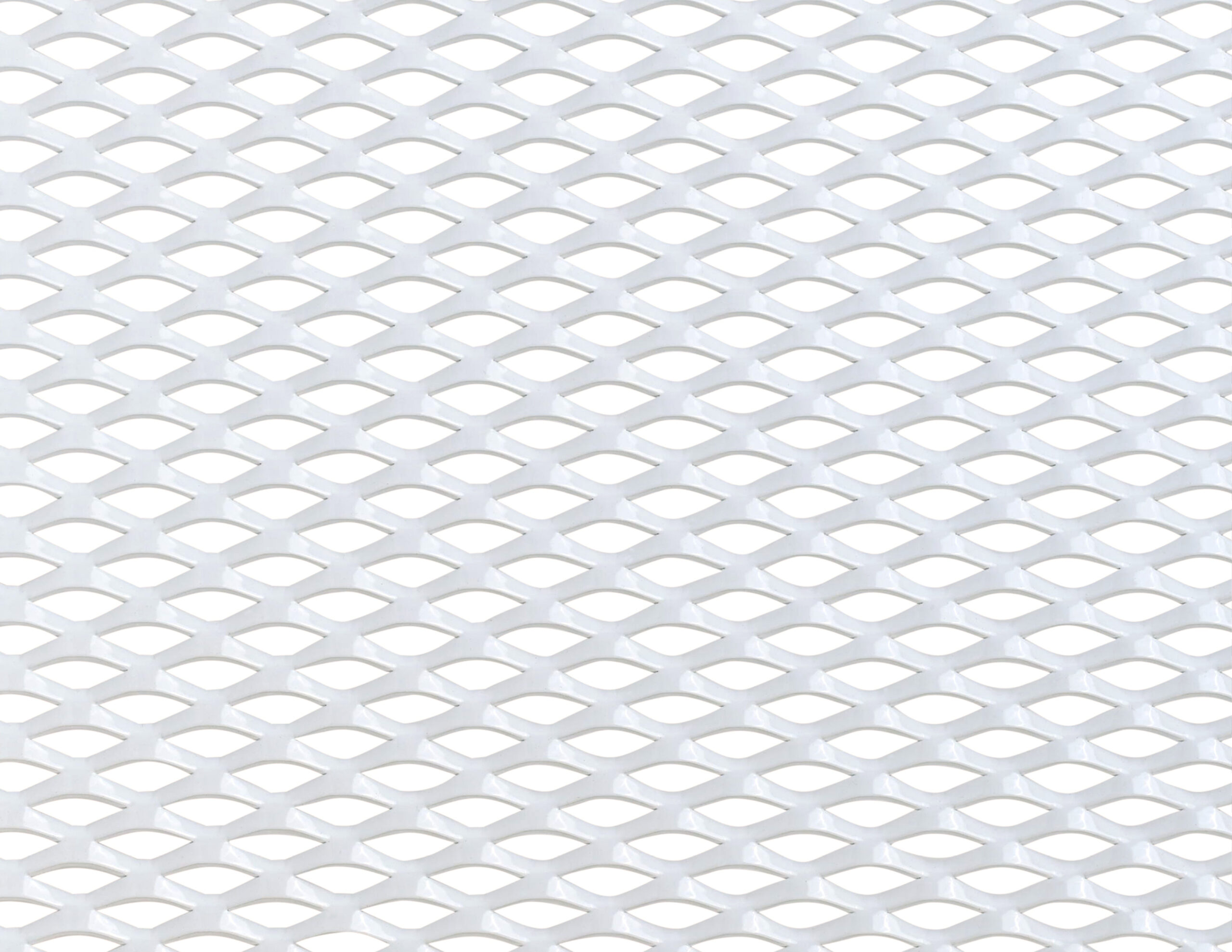

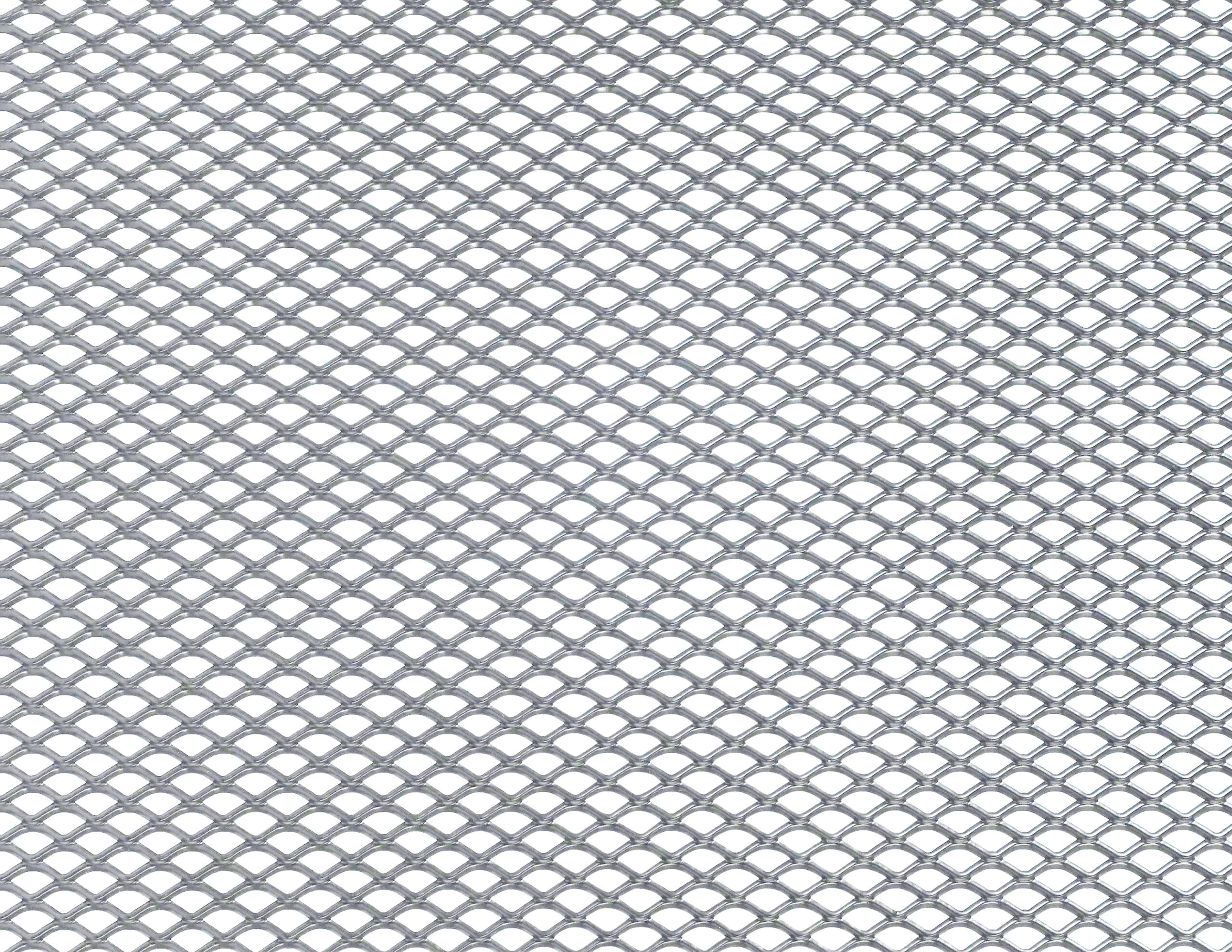

- APEX04

- APEX05

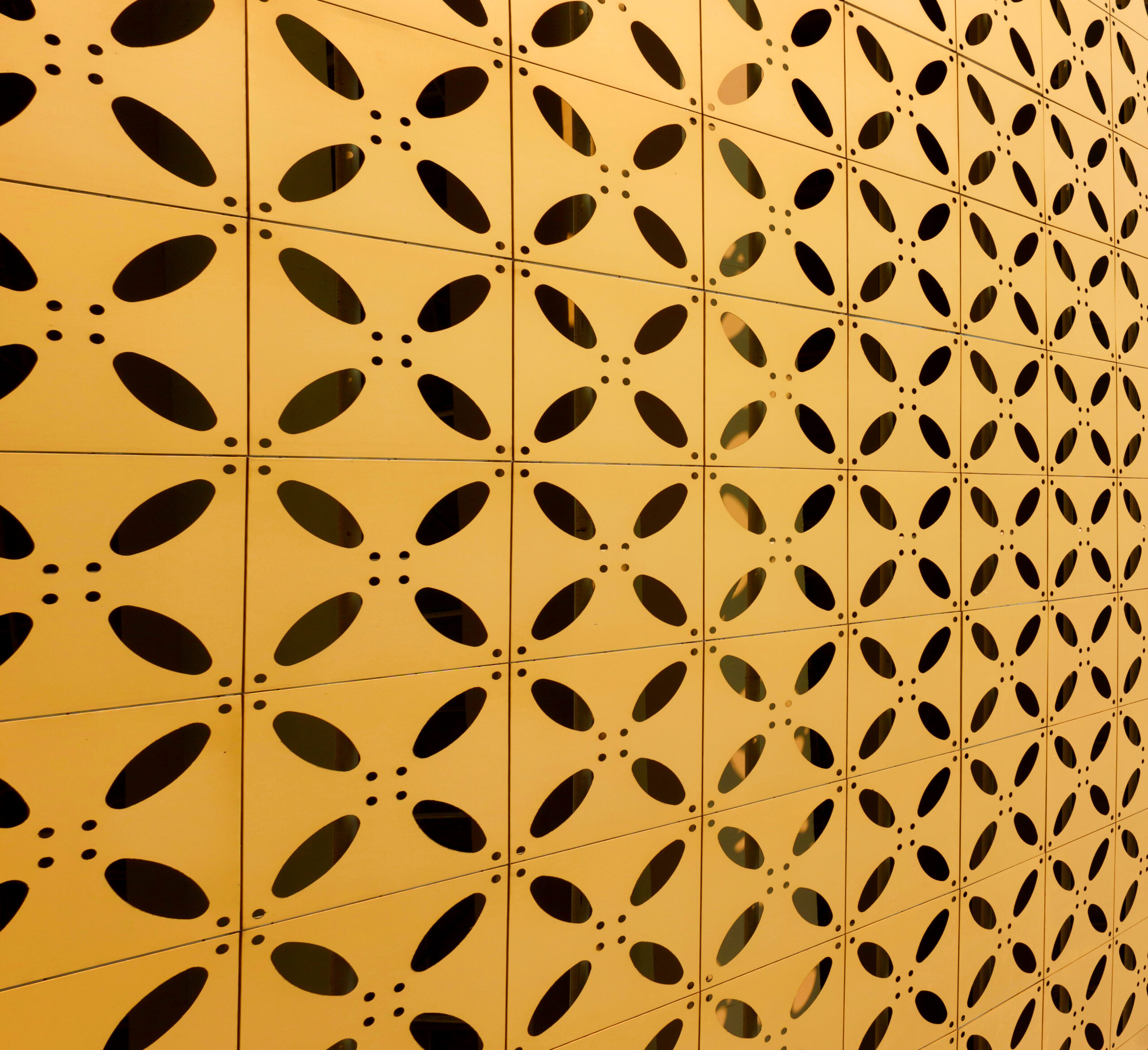

- De Moda

- Hinter

- Luxos

- Modig

- Siro

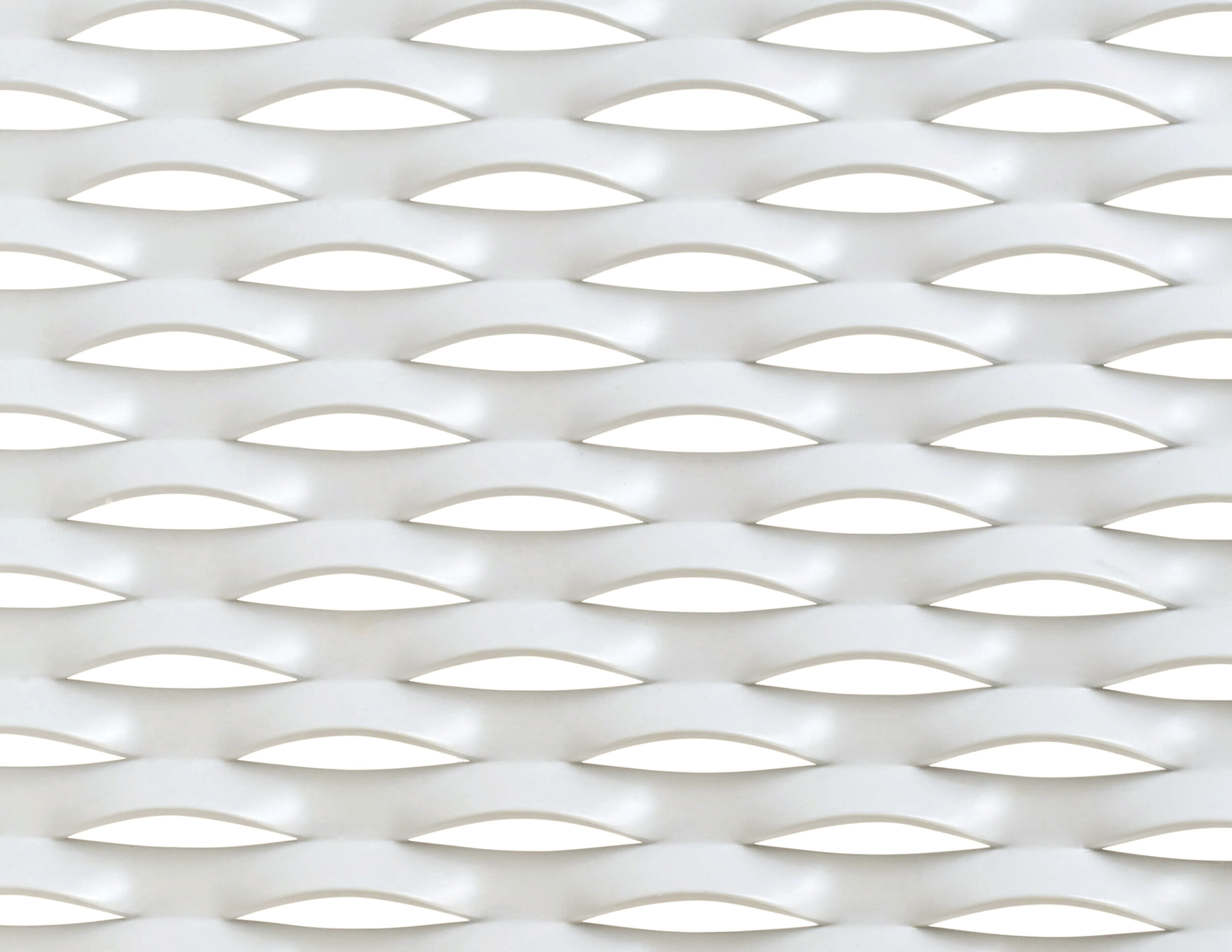

- All across perforated patterns with less than 50% open

- Custom perf and laser-cut projects will need to be evaluated on a project-to-project basis

More Fassade S information:

- AMICO – Dorken compatibility letter

- Installation Instruction

- Delta Fassade S Technical Data Sheets and 3-Part Specifications

- Dorken website pages for Delta Fassade S, Mechanically Attached and Self-Adhered products

Leave a Reply